Why Diamond Grinding Wheels are considered to be super-abrasives?

Diamond Grinding Wheel can be termed a new product introduced among grinding wheels only after synthetic materials were discovered and manufactured! Research conducted into synthetic materials is credited to have resulted in the production of synthetic diamonds, including the discovery of CBN or cubic boron nitride. Artificial diamonds are regarded as among the most complex materials discovered now. These are used mainly to manufacture grinding wheels.

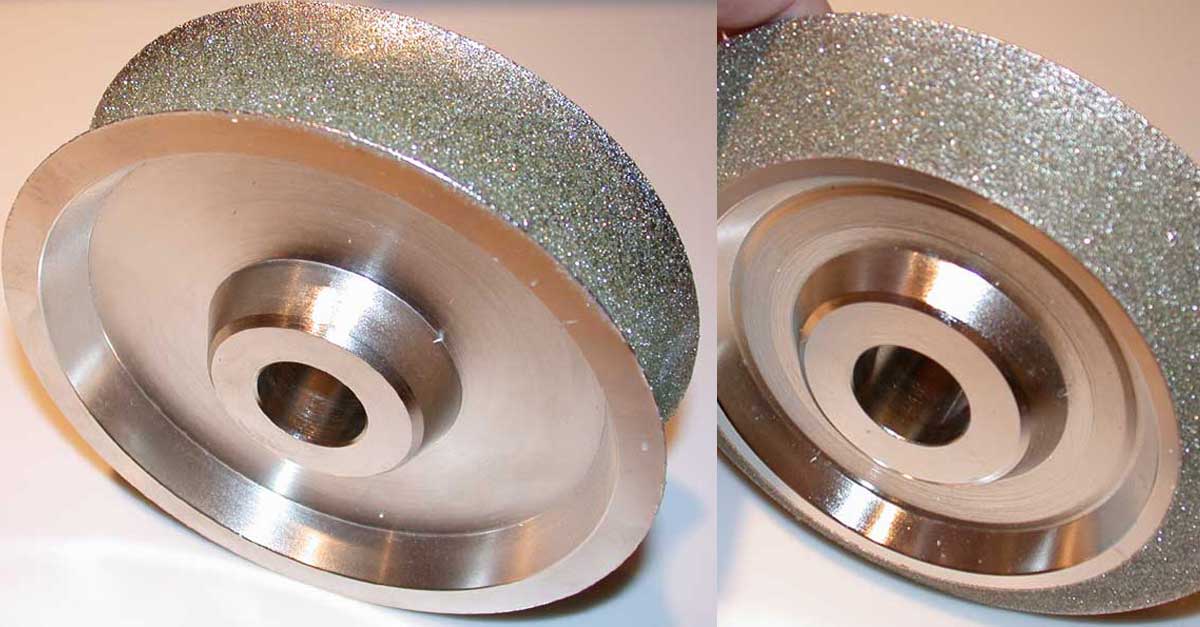

Synthetic diamonds are said to have copper and nickel coatings to ensure longevity. A Diamond Grinding Wheel is created from synthetic diamonds. They are durable, hence referred to as super abrasives.

Why are Diamond Grinding Wheels considered to be super-abrasives?

Structure

When the structure is concerned, these wheels can be found to come in different shapes like cones, cylinders, cups, flat disks, and wheels. Their profiles are cut within their periphery. Diamond is also stated to be a CBN grinding wheel. Usually, they are classified by their grit size, shape, bond, and concentration. The abrasive’s grit size is chosen for the Resin Grinding Wheel depending on the cutting material’s hardness.

Grit size

Generally, grit is used in sizes ranging from 120 to 180. This is when the grinding wheel is created for several tool room applications. Usually, finer grits of 220+ are mined in a particular order. They are meant to be used in superior quality and fine surface finishes. The abrasive concentration depends mainly on what type of application the wheel needs to serve. You can get a basic idea from the leading Resin Grinding Wheel manufacturer.

Diamond concentration in the grinding rim mainly depends on the application. To enable hardened steel or tungsten carbide stock removal, a concentration of about 75-125 is selected. However, choose 150 concentrations if the grinding wheel’s contact surface with the material is small. The Diamond Grinding Wheel manufacturer can enumerate this aspect.

When manufacturing Diamond Grinding Wheel China, another aspect involved the bone. It is generally used to keep together the abrasive grains. The grinding wheels used bonds that were refined for several years. Presently, the primary bond options are vitrified, resin, and metal bonds. They are then electroplated using resin. Metal and vitrified bonds generally cost much more and must be custom-ordered. Typically, electroplated wheels are used for cut-off wheels, including low abrasive grinding such as plastics.

Generally, Diamond Grinding Wheels tend to have specific markings to assist in their identification. For example, D1A1-150R 100-B4! Here, D1A1 means wheel shape, grit size is 150, concentration is 100, and manufacturer bond is B4.

Types

Manufacturers of Diamond and Resin, Grinding Wheel China, assign the hardiness extent of the wheel. It is achieved either by allowing the fracturing of abrasive grains or restricting fracture. As the wheel gets fractured by the abrasives easily, it is referred to as a soft bond. But hard bond wheels are designed to withstand much larger forces as fracturing gets restricted. Usually, soft wheels are used for Diamond Grinding Wheel surfaces to cut them easily. It also has a shorter life. However, rigid wheels are more durable and can be utilized in finer surface finishes.