Packing tips using case erectors

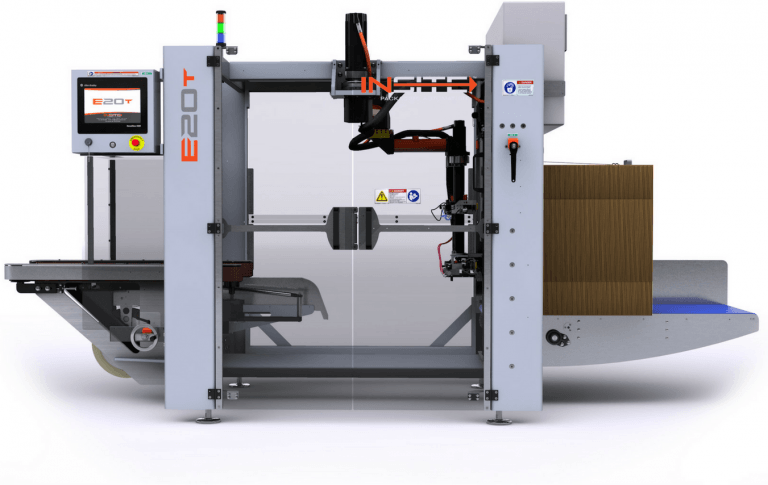

Packing is an important part of any shipping process but can be tedious and time-consuming. Fortunately, with the help of automation, packing has become more efficient than ever before. One such piece of automation equipment is a case erector which this a machine that automatically forms boxes for packing products. Case erectors are used in industries ranging from food processing to pharmaceuticals to provide a reliable way to quickly and accurately complete the packaging process. In this article, let us have some tips on how to best is of packing tips using case erectors. Read on to learn more!

Top 8 Packing tips using case erectors

Perfect Hardware

If you’re in the market for a case erector, you want to be sure to find one that’s just right for your needs. Here are a few tips to help you select the perfect hardware for your packing needs:

- Determine the size and shape of the items you’ll be packing. You’ll need to make sure the case erector can accommodate the size and shape of your items.

- Consider how many items you’ll be packing at once. You’ll want to make sure the case erector can handle the volume of items you’ll be packing.

- Determine what kind of packaging material you’ll be using. You’ll need to make sure the case erector is compatible with the type of packaging material you plan on using.

- Consider your budget. You don’t want to spend more than you have to on a case erector, so be sure to consider your budget when making your selection.

- Get expert help. If you’re not sure which case erector is right for you, it’s a good idea to seek out expert advice before making your purchase.

The complete system of packing

A case erector is a machine that is used to form cardboard boxes from flat sheets of corrugated board. The corrugated board is fed into the case erector, which then folds and glues the board to form a box.

A complete system of packing using case erectors starts with an infeed conveyor that feeds the flat sheets of the corrugated board into the case erector. The case erector then forms the cardboard boxes, which are then conveyed to a packing station. At the packing station, products are placed into cardboard boxes and the boxes are sealed. The packed boxes are then conveyed to a shipping area where they are loaded onto trucks or pallets for shipping.

Uniformly cases

If you have products that need to be securely packaged in a box, then using a case erector is the way to go. With a case erector, you can quickly and easily create uniformly-sized boxes that will protect your products during shipping and handling.

Here are some tips for using case erectors:

- Make sure that your product dimensions are compatible with the case erector. The product needs to fit snugly inside the box so that it doesn’t move around during shipping.

- Use the right size of box for your product. You don’t want the box to be too big or too small – just right!

- Choose a material that will protect your product from damage. Cardboard is a good option, but you may also want to use bubble wrap or foam padding for extra protection.

- Seal the box tightly with packing tape so that nothing falls out during transit.

- Label the box clearly with all relevant information, such as destination address, return address, and contents. This will help ensure that your package arrives at its intended destination safely and on time!

Shipping Needs

If you’re sending packages through the mail, you’ll need to use a case erector. A case erector is a machine that helps to seal and package products for shipping. There are many different types of case erectors, so it’s important to choose the right one for your needs.

Here are some tips for using case erectors:

- Make sure that the dimensions of the product you’re packaging match the dimensions of the case erector. If the product is too large or too small, it won’t be able to seal properly.

- Make sure the product is placed in the center of the case erector. This will help to ensure that it seals evenly on all sides.

- Be careful not to overfill the case. If there’s too much product, it can cause problems with sealing.

- Once the product is in place, close the lid and start sealing. Depending on the type of case erector you’re using, this may be automatic or manual.

- Once the sealing process is complete, remove the product from the case and label it accordingly.

Positive environmental Impact

When you use a case erector to pack your products, you’re not only saving time and money, but you’re also having a positive impact on the environment. By using less material to package your products, you’re reducing your company’s carbon footprint and helping to preserve our planet’s resources.

And it’s not just the packaging that’s more sustainable – the product itself will have a longer shelf life thanks to the added protection of being securely packed in a case. This means less waste and fewer returns, both of which are good for the environment.

The bottom line

Whether you’re packing for a move or preparing for shipping orders, using a case erector can save you time and money. Case erectors are machines that quickly and easily assemble cardboard boxes. So if you’re looking for a packing solution that’s good for your bottom line and good for the planet, consider investing in a case erector. You’ll be glad you did!

They’re fast, efficient, and can be used to pack a variety of items.

Time-saving

If you are packing products for shipment, using a case erector can save you a lot of time. A case erector is a machine that forms cardboard boxes from flat sheets of cardboard. This can be much faster than packing products by hand.

When using a case erector, it is important to choose the right size machine for your needs. You will also need to have the right type of cardboard. Some machines can only handle certain types of cardboard.

If you’re looking to save time and money on your packing needs, consider investing in a case erector.

It is also important to read the instructions carefully before using a case erector. This will help you avoid any accidents or damage to the product.

Atlantic tape and packing for case erectors

If you’re looking for a way to increase efficiency and decrease downtime in your packing process, investing in a case erector is a great option. Case erectors are machines that automatically fold and seal cardboard boxes, making them ideal for high-volume packaging applications. Not only do they save time and labor, but they also result in a more consistent and professional-looking product.

Atlantic Tape & Packing is a leading provider of case erectors and other packaging equipment. We offer a wide range of machines to meet the needs of any business, from small operations to large factories. Our team of experts can help you select the right model for your application and provide training on how to use it effectively. Contact us today to learn more about our products and services!

Conclusion

As you can see, using case erectors can save you a lot of time and money when packing your products. Whether you are packaging for shipping or storage, these machines can help you get the job done quickly and efficiently. If you are looking for a way to improve your packaging process, consider investing in a case erector.