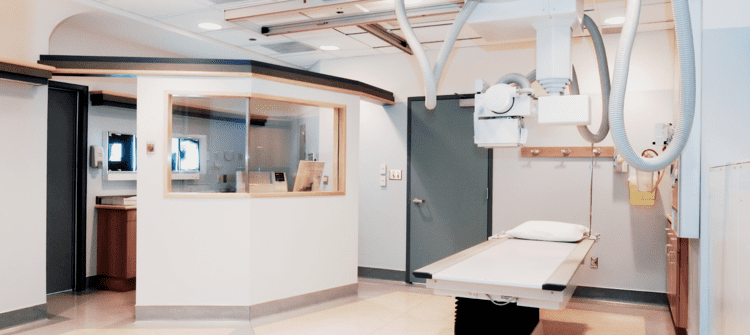

Setting up Lead Lining in X-Ray Room

An x-ray facility is intended to offer a secure environment for individuals. You can limit radiation risk by lead-lining your x-ray cabin’s walls, as well as its tops and flooring on sometimes. This safeguards both employees’ and their consumers’ health by lowering the possible health hazards associated with long-term therapy in an unsafe setting. In this piece, we’ll look at the reasons lead-lining is necessary, the three steps of lead-lining the x-ray theater, and other factors to consider.

Setting up Lead Lining in X-Ray Room

Definition of lead-lining

Lead-lining is typically made out of a lead layer that is either put to the walls or fitted into frames. The density of this coverage varies depending on how strong radiation protection you require in your space.

Functions of lead-lining

Lead-lining is required between each of the sidewalls (internal and external) and other chambers of an x-ray chamber because it protects individuals from radioactivity exposure by insulating the client both from x-rays and gamma radioactivity. It also safeguards personnel who work in close contact with customers, including radiography technicians or specialists.

Setup of lead-lining

When it relates to lead-lining the x-ray facility, there will be three major steps to consider:

Equipment room drawing and required instruments

An equipment chamber design depicts where the machinery is located as well as what is beyond the walls, such as a greeting section on one end or if the facility stands on the ground or second level.

In addition, a radioactive protection purchase form should be filled out. This application will require you to provide the structure of the component within the structure as well as the sorts of x-rays you will be conducting, such as cross-table shots. When the equipment room layout and intake form are finished, they must be submitted to a physicist.

Physicist’s advice

Depending upon that equipment area plan, the physicist can submit a report outlining precisely what amount of lead is needed for such an x-ray chamber and how thicker it has to remain in each region. They might do so based on the data supplied by the instrument room layout and radiation protection intake sheet.

That physicist’s report explaining what amount of lead is needed or why it is needed might take anything from 2-3 working days to fourteen days.

Only the operator’s area may require to get lead-lined in certain circumstances. This might be due to the cabin’s building material, such as a cement wall, or even to the barrier being an outdoor wall that does not exhibit any possible danger to persons passing by.

Setup

After the physicist’s analysis is delivered, you may acquire the lead needed for the x-ray chamber. We may have this supplied to your location and communicate with your supplier and electrician about where or how to install the lead in line with the physicist’s findings.

When the project is finished, our staff will conduct installation instructions. Install times might range from two days for chiropractor offices to three days for emergency care centers. We will next teach your employees how to use the system.

Additional consideration

It’s possible that you’ll need to lead-line the x-ray cabin’s roof and ground. This could be required when you’re at the second level of a facility, collecting x-rays on a bench and projecting downwards to the level where people are.

Chiropractic clinics utilize fewer x-rays and have lower lead demands than hospitals. Even before the physicist does calculations and generates the shielding analysis, the radioactivity shielding intake sheet details the regularity and kinds of x-rays used.

Not only must the walls of an x-ray room be lead-lined, but the operator area must also be protected. A standard x-ray room will feature an operator area behind which the radiology technician or doctor will stand. This often includes a lead-lined x-ray window, typically 12×12 inches in size that allows them to see the patient while taking the x-ray in a safe atmosphere where they are not exposed to radiation.

Final thoughts

There are several companies that can assist you if you are looking to build or upgrade an x-ray room. They can draw up your equipment room drawing, assist you in implementing the lead requirements from your physicist report, and will be with you throughout the installation process. Their team of experts is ready to help lead-line your x-ray room. Also, don’t forget to use other protective equipment like lead glasses for radiation protection.