Fully Automatic CMM for Precision Machine Shops

In the world of precision machining, accuracy, and efficiency are paramount. Precision machine shops rely on cutting-edge technologies and equipment to ensure their products meet the highest quality standards.

A perfect example of a technology that has revolutionized the industry is the Fully Automatic Coordinate Measuring Machine (CMM). CMM has become a concept of utmost importance for those who prioritize accuracy and precision in their manufacturing procedures.

The Role of Fully Automatic CMMs in Quality Control

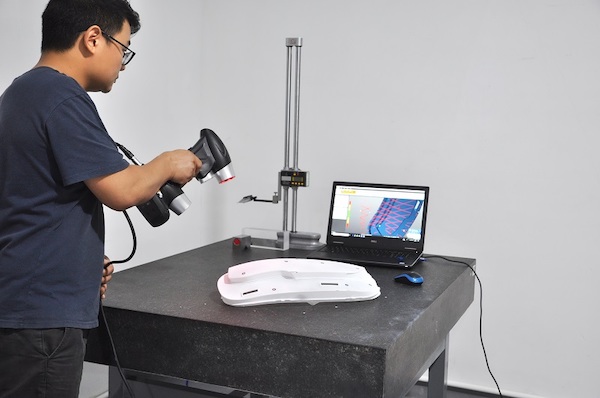

Fully Automatic CMMs are at the forefront of measurement technology, offering exceptional accuracy and efficiency. These advanced machines utilize metrology principles to carry out precise inspections and measurements. Equipped with sophisticated sensors and advanced software, Fully Automatic CMMs capture detailed measurements with incredible precision.

Precision machine shops require meticulous inspection when dealing with intricate components. These machines can detect the slightest deviations from the desired specifications. They are able to capture data from multiple angles and dimensions, which provide comprehensive and accurate measurements, and streamline the quality assurance process. Thus, high-precision machine shops can prevent costly reworks and ensure customer satisfaction. And it achieves this by identifying and correcting any discrepancies early in the manufacturing process,

In addition to delivering unmatched precision, Fully Automatic CMMs significantly enhance the efficiency of CNC machine shops. These machines are designed to automate the measurement process, eliminating the need for manual intervention and reducing the chances of human error. By swiftly and accurately inspecting machined components, Fully Automatic CMMs expedite the production cycle.

Significance of Metrology Principles in the Inspection Process

Metrology, the science of measurement, is the foundation of accurate inspections. Fully Automatic CMMs leverage metrology principles to analyze the geometric characteristics of manufactured parts.

By employing precise algorithms and advanced software, these machining shops compare the measured dimensions against the desired specifications, ensuring that the components meet the required tolerances.

Detecting Deviations and Preventing Costly Reworks

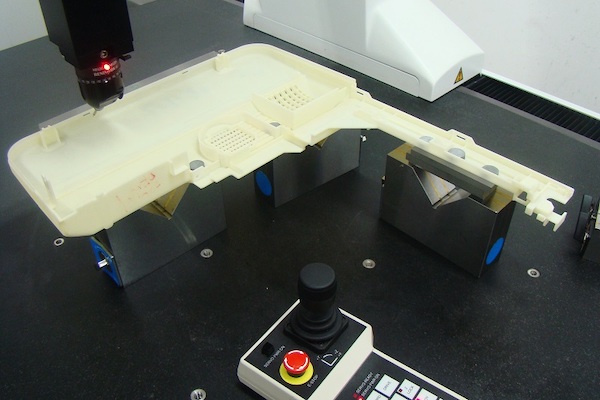

Fully Automatic CMMs excel in detecting deviations from the desired measurements. Through their high-precision machine shop probes and advanced sensors, these machines capture detailed data points on the inspected parts.

By comparing the measured data with the original CAD (Computer-Aided Design) models, Fully Automatic CMMs can identify any discrepancies or deviations.

This early detection enables manufacturers to take corrective actions promptly, preventing costly reworks and reducing production delays.

How Fully Automatic CMMs Automate the Measurement Process

Apart from maintaining accuracy, Fully Automatic CMMs streamline the measurement process by automating various tasks. Let’s explore how these machines enhance efficiency and productivity.

Programmable Operations

Fully Automatic CMMs come with sophisticated software that enables users to program measurement routines. This feature allows operators to define specific measurement paths, data collection parameters, and probe configurations in advance.

Once the program is created, the CMM can execute the entire measurement process automatically, minimizing the need for manual intervention and reducing the risk of human error.

By automating repetitive tasks, this method saves time, improves efficiency, and ensures consistent and accurate measurements across multiple parts. This way cnc precision machining shops achieve the desired results with less effort.

Advanced Probing Systems

Fully Automatic CMMs employ advanced probing systems that facilitate automatic part detection and alignment.

These systems utilize various probe types, such as touch-trigger probes or continuous contact scanning probes, to capture precise data points on the surface of the workpiece.

The CMM’s software can control the probing system to automatically move the probe along the programmed measurement path, collecting data at predefined intervals. This automation eliminates the need for manual probe manipulation, resulting in faster and more reliable measurements.

Integrated Metrology Software

Fully Automatic CMMs integrate powerful metrology software that simplifies the measurement process. The software offers a user-friendly interface that allows operators to define measurement parameters, set tolerances, and generate comprehensive reports.

Thus, with intuitive tools and features the software enables efficient and accurate data analysis.

Tools such as CAD model import, alignment algorithms, geometric dimensioning and tolerancing (GD&T) analysis help with accuracy during data analysis.

By automating data processing and analysis, fully automatic CMMs expedite the inspection process and provide actionable insights for quality control and process improvement.

Quick and Repeatable Measurements

Fully Automatic CMMs offer rapid and repeatable measurements, ensuring consistent quality control throughout the production process. These machines can perform measurements in a fraction of the time it takes for manual inspections.

More so, by eliminating human error and variability, CMMs provide reliable and consistent results,enhancing overall productivity.

Data Analysis and Reporting

Modern Fully Automatic CMMs come equipped with powerful software that enables comprehensive data analysis and reporting.

The collected measurement data can be processed and presented in various formats, including detailed inspection reports, statistical analysis, and visual representations.

This valuable information allows manufacturers to make data-driven decisions, optimize their processes, and improve product quality.

Conclusion

In the realm of precision machining, the Fully Automatic CMM stands as an invaluable tool for precision machine shops.

These advanced machines ensure unmatched accuracy, enhance efficiency, and contribute to maintaining exceptional quality standards. With their rapid inspection capabilities, seamless integration with CAD/CAM systems, and ability to improve productivity, Fully Automatic CMMs have become an indispensable asset in precision machine shops worldwide.

By investing in this cutting-edge technology, high-precision machine shops can elevate their operations, deliver superior products, and stay ahead in today’s competitive market.