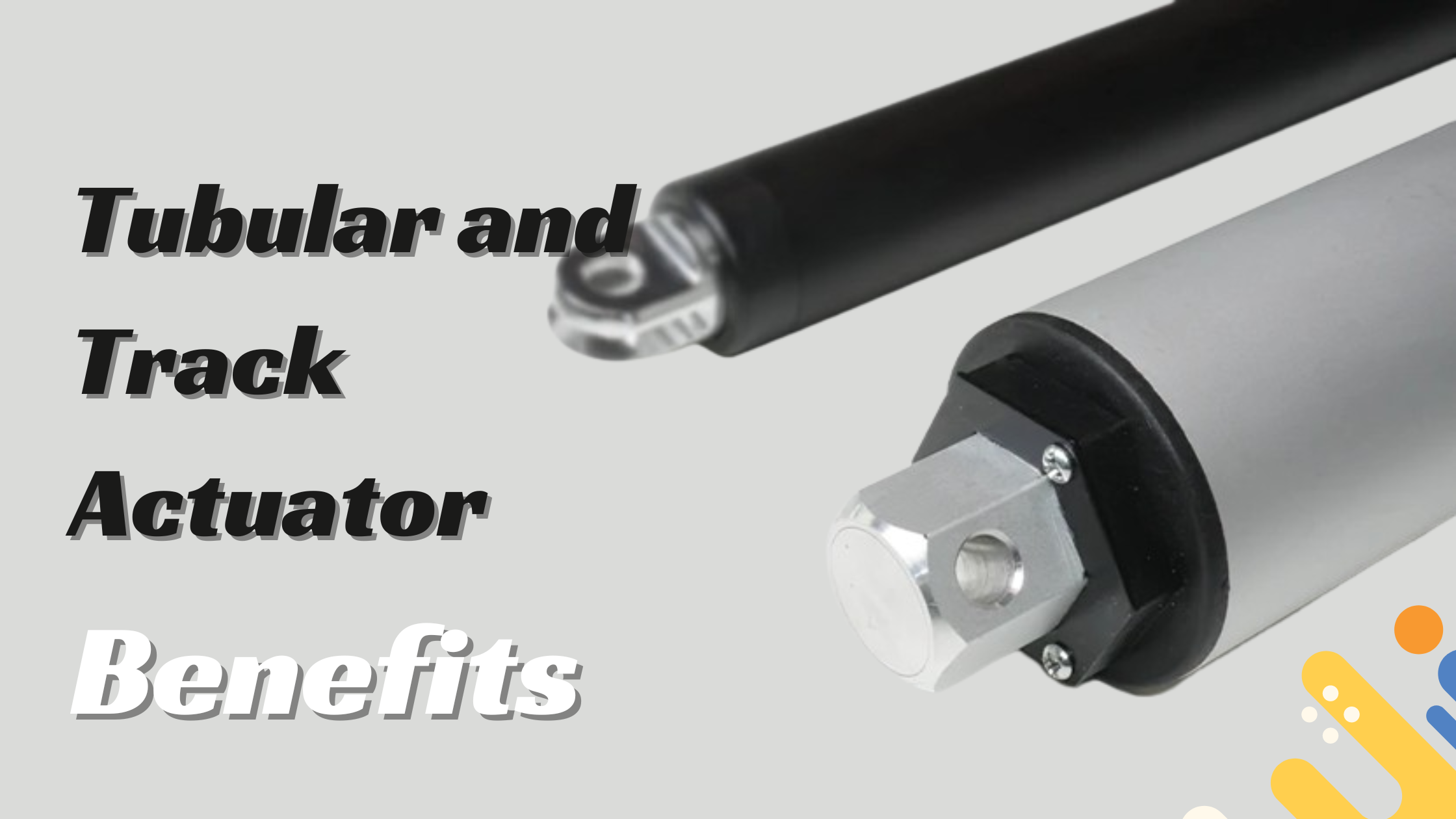

Key Advantages of Tubular and Track Actuator in Use

The design of tubular linear actuators is notably sleek, a characteristic our engineering team prioritized during their development. Incorporating an inline motor is a pivotal aspect of their design, enabling these actuators to integrate seamlessly into spaces where every millimetre counts. These actuators aren’t just about saving space; specific models boasting dynamic forces of up to 180 lbs and extended stroke lengths bring robust performance to even the most spatially constrained projects.

In direct-drive linear motors, tubular ones have carved out a niche, earning accolades for their distinct benefits. This successful tubular and track actuator combination offers precise control, rapid response capabilities, and a straightforward mechanical structure. This makes them a go-to choice for many applications across various industries, demonstrating their versatility and efficiency.

Key Work Aspects of Tubular Linear Motors

A tubular linear motor operates as a direct drive system, meaning it transforms electrical energy into straight-line motion without the need for gears, belts, or screws. This motor comprises two primary parts: the stator, which is the stationary element, and the mover, which is the moving element. The stator is designed as a cylinder with coils inside, and the mover is essentially a cylinder with permanent magnets.

The magic starts when alternating current flows through the stator’s coils, creating a magnetic field. This field interacts with the magnets in the mover to produce linear movement. Adjusting the current’s waveform lets you finely tune the motor’s movement, speed, and acceleration, leading to a highly efficient and precise linear motion system.

Significant Advantages of Applying Tubular and Track Actuator

Tubular linear motors have more pros compared to traditional linear systems, offering:

High Precision: They hit the mark with exceptional precision. Their direct drive setup eliminates the slack, bending, and wear often seen with mechanical systems. This means you get spot-on accuracy and consistent performance every time.

Quick to React: These motors are all about speed and agility. They accelerate and decelerate in the blink of an eye, adapting swiftly to changing needs. They are perfect for tasks that require quick, accurate movements.

Low Upkeep: Fewer moving parts mean less can go wrong. This translates to fewer breakdowns and less money spent on repairs, boosting reliability.

Space-Saver Design: Their slim, cylindrical shape means they take up less room and are lighter than other linear motors. This gives you more freedom in design and makes them a breeze to fit into tight spaces.

Where They Make a Difference

Tubular linear motors are in demand in various sectors thanks to their standout features:

Automation and Robotics: Their precision and speed are ideal for robotic arms and machines that need quick and exact movements.

Medical and Pharmaceutical: In fields where accuracy and dependability are non-negotiable, these motors are perfect for handling medications and samples and powering medical imaging equipment.

Semiconductor Manufacturing: In an industry where exactness is everything and dust is the enemy, these motors are vital for handling delicate wafers and conducting inspections.

In summary, tubular linear motors are a game-changer, offering high precision, fast responses, low maintenance, and compact design, making them a smart pick for various industries.

Versatile Applications of Tubular Linear Motors

Tubular linear motors excel in material handling and packaging. They provide the swift, accurate, and continuous motion needed for conveyors, sorting systems, and palletizing machines. Their compact size and dynamic capabilities make them perfect for these roles.

These motors deliver the precision and stability required in research and development, especially in areas like nanotechnology, biotechnology, and advanced materials. They power equipment like nanopositioning stages, atomic force microscopes, and scanning electron microscopes, facilitating groundbreaking research.

The entertainment sector benefits from tubular linear motors in motion simulators and virtual reality setups, where their ability to execute rapid, fluid movements enhances the realism of user experiences.

Due to technological advancements, tubular linear motors are set to play an increasingly pivotal role. Research is ongoing to boost their performance, efficiency, and reliability, broadening their use in various fields. The growing emphasis on energy-efficient and eco-friendly motion solutions is also expected to spur further innovations and adoption in the industry.

Conclusion

In conclusion, tubular linear motors stand out for their benefits, including unmatched precision, rapid response times, minimal maintenance needs, and sleek design. These qualities have paved the way for widespread use in many sectors, from automation and robotics to healthcare, semiconductor production, motion control, material handling, research, and entertainment. As research and innovation continue, these motors are on track to play an even more integral role in the evolution of linear motion technology.