Why Temperature Regulation Is Key to Protect Large Equipment

If you own or operate large pieces of equipment or machinery, you must manage the large amount of heat they generate. When the heat isn’t properly managed, it can cause the equipment to overheat, which can cause a malfunction and, in some cases, a fire.

Temperature-controlled water pumps maintain a consistent temperature in a circulating system with no control valve. Some use case examples include boiler shunts, heating and cooling systems with 3-way valves, and hot water circulation.

You probably already know the importance of preventive and predictive maintenance in extending the life cycle of heavy machinery and maintaining reliability. Temperature regulation is a huge factor that can’t be skipped.

Industries that use temperature control devices

Temperature control is utilized across a wide variety of industries, including:

- Food and beverage processing

- Industrial processes

- Data centers

- Healthcare facilities

- And more

There are many different ways to do it, but regardless of the equipment, temperature regulation plays a crucial role in protecting large equipment. Here’s why it’s so important.

Heat can melt essential components.

Excessive heat can cause an entire machine to overheat, melt internal components, and render them useless. If those components catch fire, depending on the equipment’s design, it can cause even more damage and possibly lead to an explosion.

It won’t take much heat to melt if anything is made from rubber or plastic. Metal can also melt, although it will take higher temperatures. Unfortunately, high temperatures come quickly and easily during a malfunction, so you can’t avoid extensive damage once heat generation is out of control.

Excess, unregulated heat can cause a fire.

Whenever a large piece of equipment generates an excessive amount of heat, it can catch fire. For example, transformers are known to catch fire when they fail, and the reason for the failure is almost always poor insulation. The insulation in a transformer is supposed to absorb and dissipate the heat steadily. When that insulation is made from inferior materials or improperly wound, there is little to no heat regulation, leading to failure.

A high-efficiency transformer will produce less heat waste because it regulates heat better. It’s less likely to fail prematurely and far less likely to explode or catch fire. If an inefficient transformer is installed inside a building or in an outside area where people work, it can become a safety hazard. The problem is that you can’t always predict if or when a transformer might explode, although there are signs that a unit is failing.

Many factors impact temperature

When managing any equipment, it’s essential to recognize all the variables that impact temperature. For example, simply using a lubricant with the wrong viscosity or a contaminated lubricant can increase heat. The same goes for placing excessive loads on components, too much speed, and accumulating dirt and debris.

Sometimes, people add grease to an already overheated bearing, which causes it to overheat even more by creating additional friction. Grease is also an insulator. In this case, when the temperature rises, the oil film thins out and creates more friction that can eventually cause the bearings to fail. Companies use oil misting systems to combat this issue, so there is never excessive lubricant build-up.

Where dust and debris are concerned, it’s a big deal. Even the Society of Tribologists and Lubrication Engineers (STLE) say,

The cleanliness of lubricants related to bearing surfaces should be as important to the bearing user as antiseptic measures are to the surgeon.

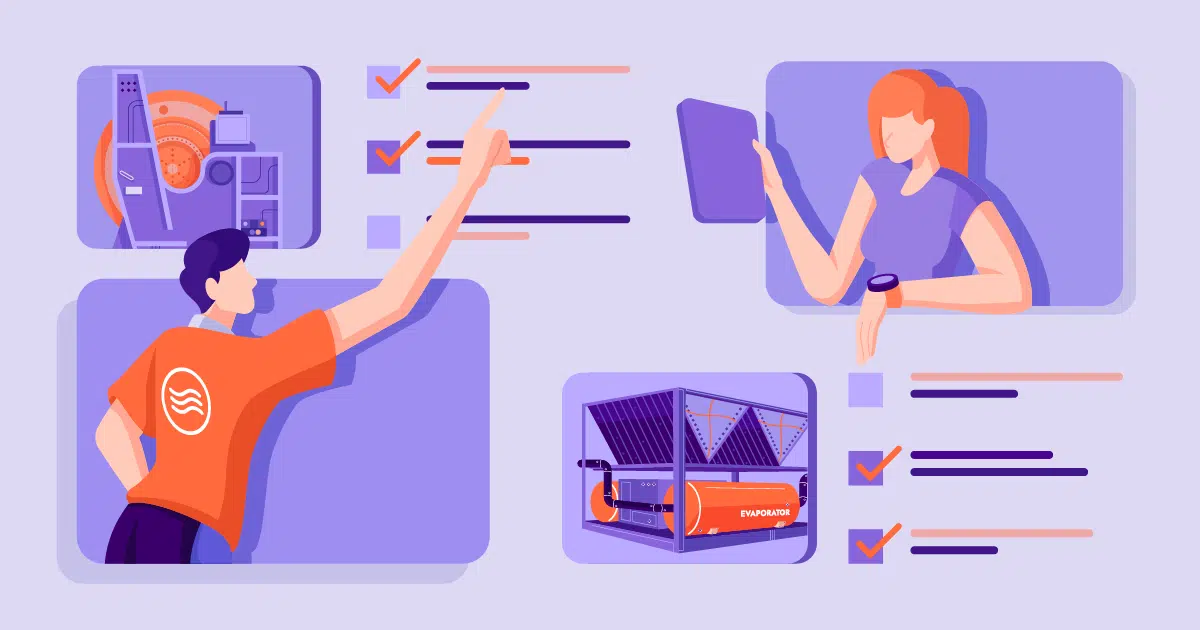

Heat regulation is crucial to maintaining large equipment

Whether it’s a piece of construction equipment, like a tractor, or machinery at a large-scale industrial facility, you must regulate heat efficiently to prevent breakdowns and catastrophic disasters.

Ensure you have the proper infrastructure in place; if you are unsure, consult a professional.