How much does a PCB cost?

Printed circuit boards (PCBs) have become a necessity in modern electronics. Although they have been used for many decades, PCB engineers and designers continue to make them powerful, reliable, and smaller.

Due to complexity, a PCB’s cost is determined by several factors. So, to know how much a PCB costs, you need to look into aspects that go into manufacturing them.

How much does a new circuit board cost?

Normally, the cost of producing a printed circuit board is between $10 and $50 per board. However, the cost is determined by several factors, including the type of board, number of layers, and size.

What are the main factors that affect the cost of a Printed Circuit Board?

Type of PCB material

Printed circuit boards are made of various materials, including polymer inks, fiberglass, and solder masks. The conductive layers are typically silver, gold, or copper.

The above materials can affect the cost of a PCB and the way the board reacts to heat. Circuit boards have thermal and temperature reliabilities, and they should have mechanical properties that might affect the board’s performance.

Therefore, the materials you use when making a PCB can easily affect the cost. The price will be higher than standard materials if you use higher-grade materials.

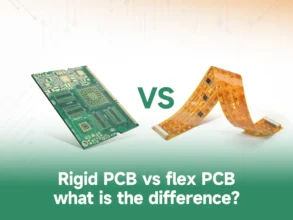

PCB size and the number of layers

Other factors determining the cost of a printed circuit board are board size and the number of layers. Some circuit boards have more layers than others.

Printed circuit boards that run high-tech electronics have many layers. They are composed of several layers and have components on both sides of the board. Thus, a board that needs many elements will cost more than a circuit board with fewer components.

Moreover, a large circuit board costs more than a smaller board. This is because the space that consumes the elements increases the cost of the PCBs. The price is higher because of the large board and because it takes more time to manufacture several layers.

Size of circuit board holes

The size of the circuit board holes is another factor that can affect the cost of production. This is because the holes need precise drilling or CNC milling, which is different when the circuit boards are compact or thick.

The holes are essential because they help the printed circuit board fit together and send messages through various components.

Cost of labor

Another vital element that affects the cost of producing a printed circuit board is the cost of labor. First, you need to engage experts to handle the job. In addition, you need automated machinery made explicitly for PCB manufacturing.

The labor cost affects production because no one wants to work with inexperienced workers. It would be best to have skilled and knowledgeable people create a PCB’s essential components.

It is wise to pay the staff generously to ensure they build high-quality circuit boards. You do not want to have low-produced printed circuit boards.

Expected turnaround time

Turnaround time is another factor you cannot ignore when producing PCBs. It can highly affect the production cost. Some manufacturers produce the boards quickly.

However, they charge more when a PCB manufacturer is asked to build printed circuit boards quickly. This is because they need to put you on hold for other orders to turn around your order.

So, if you would like to reduce the production cost, placing your orders as early as possible is essential. This will ensure you give the manufacturer enough time and do not force them to pay over time.

The quality of the order

When you produce PCBs in bulk, you can lower the production cost. Moreover, once you create a prototype, it is easy to duplicate the order. Even though building a prototype is expensive, it can save you time and money in the long run.

Technology used

The technology a PCB manufacturer uses to build a circuit board also affects the cost of production. Various types of technology are used.

For example, there is through-hole technology and surface-mount technology. The surface mount is less than through-hole technology because it is more automated and needs less workforce.

Other unique specifications

Your custom specifications also determine the cost of the PCB. Hence, if you want to reduce the cost of production when creating a circuit board, it is wise to have a few customer specifications. You can try using component designs from other boards to reduce the costs.

What should you consider when looking for a PCB manufacturer?

Before choosing a circuit board manufacturer, it is essential to consider all the other factors. There are so many things you need to consider, such as the type of PCB you want to build.

For example, you should not contact a PCB manufacturer that builds high-tech washing machine boards when you want to create circuit boards for smartphones.

Therefore, look for a PCB manufacturer who meets all your needs. Consider factors such as skills, experience, cost, technology, and others. Hence, make sure you research the manufacturer before hiring them.

Once you find a manufacturer who meets your needs, check to see if they produce high-quality circuit boards at an affordable price.