Revolutionizing Product Identification with Flag Labellers

- 1 The Key Role of Flag Labeling

- 1.1 Utilization in Marketing and Branding

- 1.2 Political Significance and Symbolism

- 1.3 International Relations and Diplomacy

- 1.4 Cultural Identity and Heritage

- 1.5 Navigating Challenges and Controversies

- 2 How Flag Labellers Operate

- 3 Benefits of Implementing Flag Labelers

- 4 Considerations for Choosing a Flag Labeler

- 5 The Future of Flag Labeling Technology

- 6 Conclusion

In today’s fast-paced manufacturing and distribution sectors, the accuracy and efficiency of product labelling have never been more critical. Among the myriad of labelling solutions, flag labellers emerge as a pivotal innovation, especially for items with long, circular cross-sections like cables, wires, and tubing. These specialized machines enhance the legibility and durability of labels and streamline the labelling process, ensuring products are market-ready with minimal delay.

The Key Role of Flag Labeling

Flag labelling is fundamental to product identification, safety compliance, and brand recognition. By securely attaching labels that flag out from the product, these labellers facilitate easy reading and scanning without manipulating the product. This is particularly advantageous in industries where precise identification, such as electrical wiring in construction or medical tubing in healthcare, can significantly impact safety and functionality.

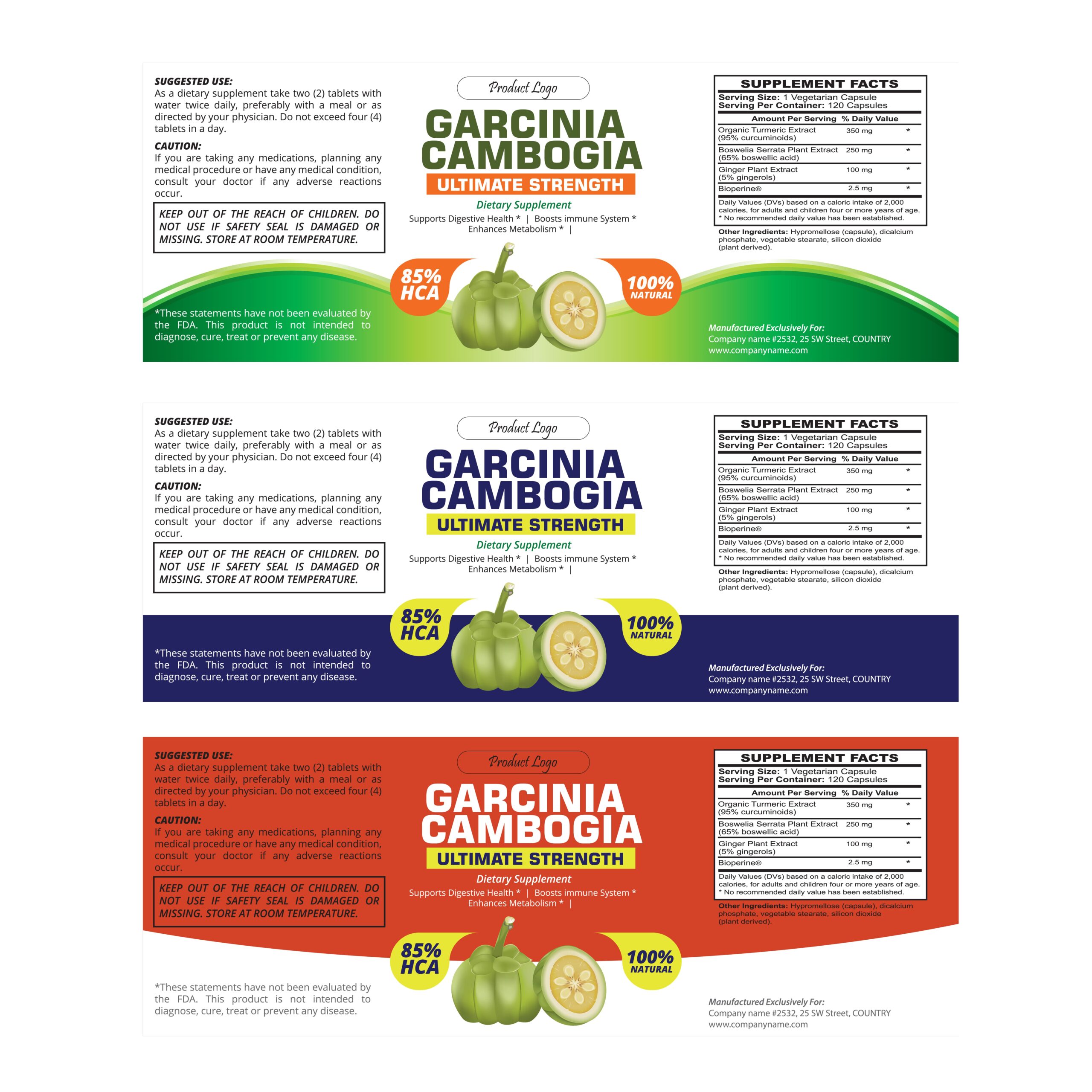

Utilization in Marketing and Branding

In marketing and branding, flag labelling creates brand identity and communicates values. Companies often incorporate flags into their logos or packaging to signify their origin or target market. For example, a company may use a national flag to indicate that its products are made in a specific country, leveraging consumer perceptions of the quality or authenticity associated with that region.

Political Significance and Symbolism

Flags hold significant political symbolism and represent nations, movements, or ideologies. Flag labelling in politics involves displaying flags during rallies, protests, or official events to assert identity or make political statements. The choice of flag and its display can evoke patriotism, solidarity, or dissent, depending on the context and audience.

International Relations and Diplomacy

In international relations, flag labelling is crucial for diplomatic protocol and symbolism. Flags are prominently displayed during state visits, summits, and negotiations to represent participating countries and their interests. Diplomatic gifts often feature flag labelling to emphasize cultural ties and diplomatic relationships between nations.

Cultural Identity and Heritage

Flags are also integral to expressing cultural identity and heritage. Communities, ethnic groups, or regions often adopt flags to symbolize their unique identity and history. Flag labelling in this context preserves cultural heritage, fosters pride, and strengthens social cohesion within diverse communities.

Navigating Challenges and Controversies

Flag labelling can be contentious despite its widespread use, especially in sensitive political or cultural contexts. Misuse or misrepresentation of flags can lead to misunderstandings, protests, or diplomatic disputes. Additionally, symbols on flags may carry different meanings across cultures, requiring careful consideration and sensitivity in their use.

How Flag Labellers Operate

Flag labeller machines are designed to apply labels automatically in a flag-like manner. The operation involves feeding the product through a mechanism where a label is wrapped around it so that the label extends out, resembling a flag. This method ensures that the label is securely fastened and prominently displayed.

Key features of flag labellers include:

- Precision Application: Ensuring labels are applied to every item’s desired location.

- High-Speed Processing: Capable of handling a high volume of products per minute, making them ideal for large-scale operations.

- Versatility: Adjustable settings allow labelling of various product sizes and materials.

- Durability: Labels applied by flag labellers are designed to withstand harsh conditions, including extreme temperatures and handling.

Precision Application:

Flag labellers are engineered precisely, ensuring labels are accurately applied to the desired location on each item. This precision is crucial for maintaining consistency and adherence to branding standards. Whether positioning a label on a specific area of a product’s packaging or ensuring alignment with graphics or text, flag labellers excel in delivering precise applications.

Using advanced technology such as sensors and computerized controls, flag labellers can detect and adjust for product size, shape, or orientation variations, ensuring that labels are placed accurately every time. This level of precision minimizes wastage and enhances the overall appearance and professionalism of the labelled products.

High-Speed Processing:

Flag labellers are designed to meet the demands of high-speed production environments, capable of processing many products per minute. This feature is particularly advantageous for industries with large-scale manufacturing operations, such as food and beverage, pharmaceuticals, and consumer goods.

Flag labellers can operate seamlessly at high speeds without compromising accuracy or reliability, and they are equipped with robust motors, conveyor systems, and efficient label dispensing mechanisms. This high-speed processing capability translates to increased productivity, reduced production time, and greater throughput, ultimately contributing to overall operational efficiency and profitability.

Versatility:

One of the critical features of flag labellers is their versatility, enabling them to label a wide range of product sizes, shapes, and materials. Whether cylindrical containers, flat surfaces, or irregularly shaped items, flag labellers can easily adjust to accommodate different labelling requirements.

Operators can fine-tune the label application process with customizable settings and adjustable configurations to suit specific product dimensions and packaging formats. This versatility eliminates the need for multiple labelling machines for different products, streamlining production processes and reducing equipment costs.

Additionally, flag labellers are compatible with various label materials, including paper, plastic, and metallic substrates, offering flexibility in label design and application. This adaptability makes flag labellers versatile for diverse labelling needs across various industries.

Durability:

Labels applied by flag labellers are engineered for durability. They can withstand harsh environmental conditions and handling throughout the product lifecycle. These labels maintain their integrity and adhesion if exposed to extreme temperatures, moisture, or rough handling during transportation and storage.

Manufactured using high quality materials and adhesives, flag labellers’ labels exhibit excellent resistance to fading, smudging, and abrasion, ensuring long-lasting visibility and legibility. This durability is essential for products subjected to challenging conditions, such as outdoor environments, refrigeration, or industrial settings.

Furthermore, flag labellers incorporate advanced label dispensing mechanisms that minimize label wastage and prevent adhesive buildup, contributing to overall label durability and reliability. As a result, products labelled by flag labellers maintain their professional appearance and branding impact, even in the most demanding environments.

Benefits of Implementing Flag Labelers

Integrating flag labourers into production lines offers numerous advantages:

- Enhanced Productivity: Automating the labelling process reduces manual labour and increases throughput.

- Accuracy and Consistency: Every label is applied precisely, minimizing errors and waste.

- Improved Traceability: Clear, durable labels enhance the traceability of products throughout their lifecycle.

- Regulatory Compliance: Ensures industry standards and regulations are followed when labelling products.

- Cost Efficiency: Reduces material wastage and operational costs associated with manual labelling errors.

Considerations for Choosing a Flag Labeler

Selecting the suitable flag labeller involves several considerations to ensure it meets the specific needs of your operation:

- Product Specifications: Assess the product size, shape, and material to be labelled.

- Label Requirements: Consider the type of label, including size, material, and adhesive properties.

- Operational Volume: Evaluate the volume of products that will be processed to determine the required speed and durability of the machine.

- Integration: The labeller should seamlessly integrate with existing production lines and software systems.

The Future of Flag Labeling Technology

As technology advances, flag labellers become more sophisticated, incorporating touchscreen controls, programmable settings, and enterprise resource planning (ERP) systems integration. We can expect further innovations, such as enhanced data connectivity for real-time tracking and analytics and more sustainable labelling solutions.

Conclusion

Flag labellers significantly advance automated labelling, offering efficiency, accuracy, and reliability. As businesses seek ways to improve their operational workflows, adopting such technologies will play a pivotal role in maintaining competitiveness and ensuring product integrity in the market.