Exploring Emerging Trends in Thermal Evaporation Technology for Thin Film Deposition

- 1 What is Thermal Evaporation?

- 2 What Are The Current Emerging Trends In Thermal Evaporation?

- 2.1 Pushing the Boundaries of Miniaturization

- 2.2 Controlled Evaporation Improves Precision

- 2.3 A New Frontier in Organic Electronics

- 2.4 Using Solar Power for Renewable Energy

- 2.5 Optics and Defence Using High-Tech Coatings

- 3 Thermal Evaporation Methods

- 3.1 Final Thoughts

The landscape of technology has been steadily expanding, driven by the ceaseless quest for smaller, faster, and more energy-efficient devices. A crucial cornerstone of this development is the continuous evolution of thermal evaporation technology for thin film deposition. This tried-and-true method of crafting thin films on a nanometric scale has emerged at the epicentre of new technological innovations. In today’s piece, we’ll navigate through the current state and emerging trends of thermal evaporation technology that are reshaping the future of thin film deposition.

What is Thermal Evaporation?

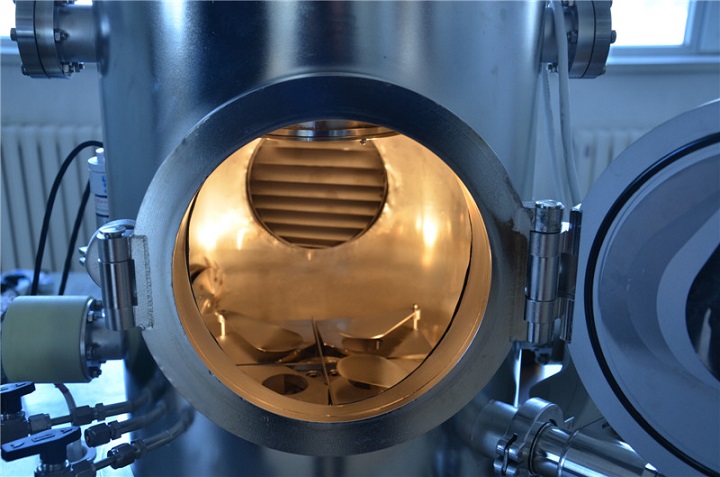

Before we get started on the trends, let’s take a step back and define thermal evaporation. Thermal evaporation is a physical vapour deposition (PVD) technology that evaporates material from a thermal source in a vacuum. This evaporated material then moves around the chamber before settling and forming a thin layer on a substrate. This technique has long been used to deposit materials such as metals and organic compounds onto various substrates, from semiconductor wafers to optical components.

What Are The Current Emerging Trends In Thermal Evaporation?

Thermal evaporation is witnessing the emergence of various trends, particularly in thin film deposition techniques and the deposition of high-performance materials. It includes:

Pushing the Boundaries of Miniaturization

As we push the limits of technical capability, we need smaller and thinner components. Thermal evaporation technology has risen to the occasion, adapting to meet the demands of next-generation electronics and nanotechnology. The increased emphasis on reducing power consumption and increasing efficiency has resulted in the development of ultrathin layers, which can only be done with precision through developments in thermal evaporation technologies. The era of ‘ultrathin’ is undeniably here.

Thermal evaporation is increasingly used with 3D printing to build complicated structures and functional gadgets. Combining additive manufacturing techniques with thin film deposition can create complex and multi-material 3D-printed items with greater functionality. This integration brings new opportunities for flexible electronics, microfluidics, and biological devices.

Controlled Evaporation Improves Precision

One of the most intriguing advances in thermal evaporation technology is developing ways to precisely manage the evaporation process. Incorporating real-time monitoring and feedback loops into the thermal evaporation process, for example, allows for fine control over layer thickness and composition. Furthermore, advanced analytics have enabled the prediction and control of the deposition process, opening the path for more efficient production and improved final products.

Molecular Beam Epitaxy (MBE) is another new technology that includes the deposition of materials in an ultra-high vacuum environment. MBE provides:

- Extraordinary control over film growth.

- Allowing for the creation of atomically accurate thin films and heterostructures.

- Making it very useful for semiconductor and optoelectronic applications.

Atomic Layer Deposition (ALD) is used with thermal evaporation to create highly homogeneous and conformal coatings. ALD enables nanometer-scale film thickness control and can be used to deposit complex multi-layer structures, allowing the manufacture of advanced devices such as integrated circuits, solar cells, and sensors.

A New Frontier in Organic Electronics

Organic electronics, with its promise of flexible, wearable technology, has reignited interest in thermal evaporation technology. The utilisation of organic materials in the manufacture of electronic devices opens up many possibilities, including the possibility of bio-compatible electronics and flexible displays. Organic semiconductors, for example, are gaining popularity for flexible electronics such as wearable gadgets and organic light-emitting diodes (OLEDs). Thermal evaporation provides a versatile and cost-effective process for depositing organic semiconductors, enabling the development of flexible and lightweight electronic devices.

Thermal evaporation is also being investigated for creating high-temperature superconductors with negligible electrical resistance at low temperatures. These superconductors have enormous promise for energy transfer, medical imaging, and quantum computing. The ability to produce high-quality superconducting films via thermal evaporation opens up new avenues for technological advancement.

Using Solar Power for Renewable Energy

The increased demand for renewable energy sources, particularly solar electricity, has resulted in an intriguing shift in the use of thermal evaporation technology. This method, in particular, has emerged as an important tool in the fabrication of thin-film solar cells. Because of its capacity to produce high-purity, defect-free films, it is an excellent choice for depositing many semiconductor materials. This is a significant step toward mass manufacturing efficient, low-cost solar cells and, ultimately, a more sustainable future.

Another essential concern is optimising the energy usage of thermal evaporation systems. Innovative designs and energy-efficient heating technologies can greatly minimise deposition energy use. Thermal insulation, energy recovery systems, and process optimisation can all help to improve overall energy efficiency.

In addition, recycling solutions for used materials are being investigated to reduce waste generation. Physical vapour deposition (PVD) recycling techniques, for example, allow for the recovery and reutilization of deposited materials, lowering the environmental effect associated with material consumption.

Optics and Defence Using High-Tech Coatings

Thermal evaporation is making waves in areas other than electronics. The demand for high-performance coatings in industries such as optics and defence, for example, has motivated researchers to employ thermal evaporation technology. The technology enables the deposition of a wide range of materials, allowing for the developing of sophisticated coatings with unique qualities such as anti-reflective, hydrophobic, or even “invisible” to radar.

Thermal Evaporation Methods

Here are some of the commonly used thermal evaporation methods:

- Resistive Heating Evaporation: This method uses a resistive filament or boat made of refractory material (e.g., tungsten or tantalum) to heat the material, causing it to evaporate.

- Electron Beam Evaporation: A focused electron beam heats the material, allowing precise control over the evaporation process, making it ideal for applications requiring high film quality and uniformity.

- Induction Heating Evaporation: An induction coil generates an oscillating magnetic field, heating a conductive crucible (e.g., copper or graphite) and evaporating the material, providing a controlled environment for highly reactive materials.

- Flash Evaporation: Material is heated to high temperatures in a container and rapidly evaporates when a shutter is opened; useful for low vapour pressure materials or directional deposition.

Final Thoughts

Thermal evaporation technology is driving trends in thin film deposition, including miniaturisation, precise control, and applications in organic electronics and renewable energy. It enables the development of ultrathin layers and the integration of additive manufacturing for complex 3D-printed structures. With advancements in molecular beam epitaxy and atomic layer deposition, it offers precise control for semiconductor applications and the production of advanced devices.

Additionally, thermal evaporation plays a crucial role in depositing organic semiconductors for flexible electronics and fabricating thin film solar cells for renewable energy. These trends highlight the importance of collaboration and innovation in leveraging the potential of thermal evaporation technology to develop smaller, faster, and more sustainable devices in various industries.