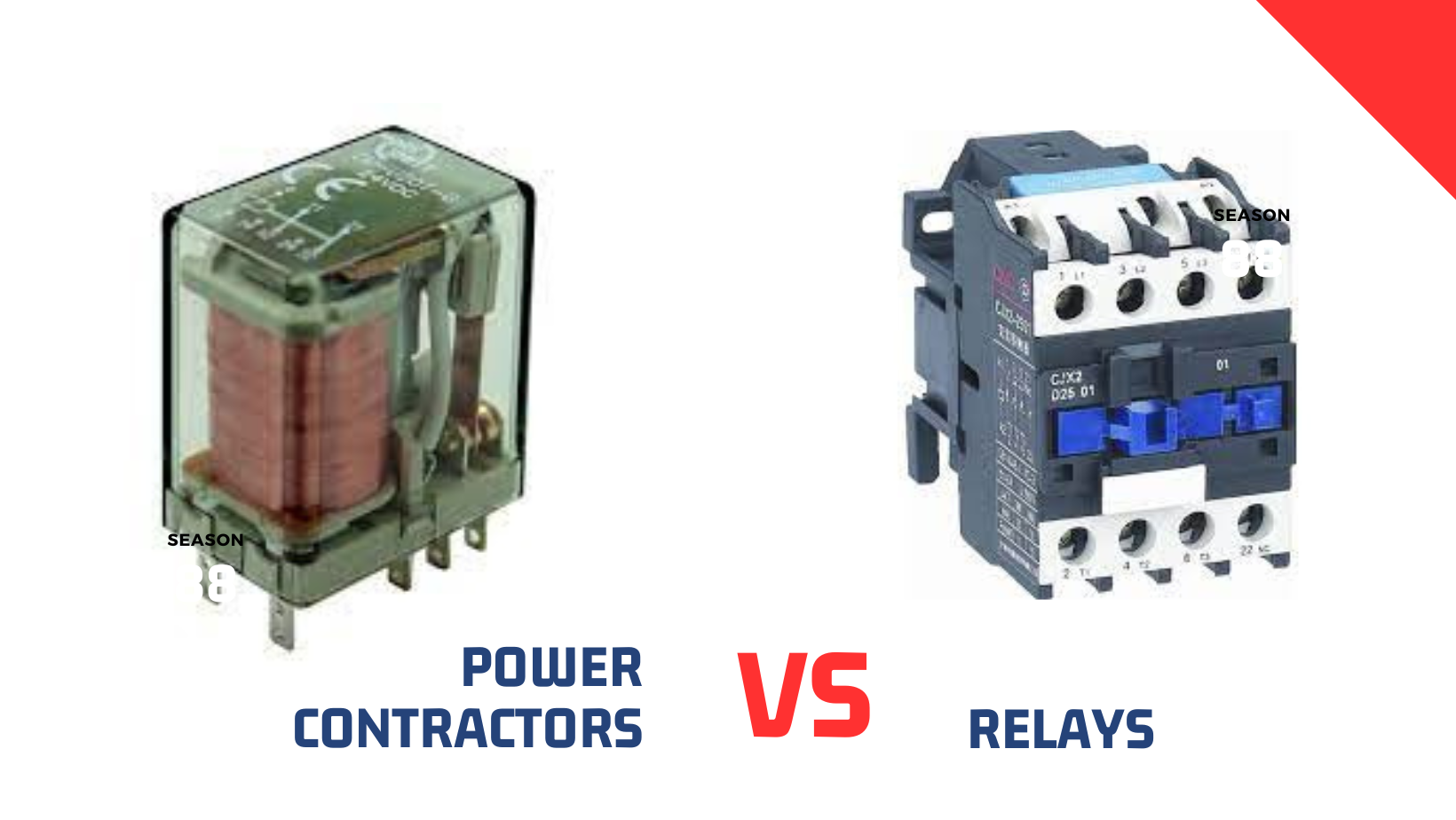

Power Contactors vs. Relays: Choosing the Right Switching Device for Your Application

- 1 Power Contactors

- 1.1 Key Features

- 1.1.1 High Current Rating:

- 1.1.2 Built-in Overload Protection:

- 1.1.3 Suitable for Frequent Switching Operations:

- 1.2 Common Application

- 2 Relays

- 2.1 Key Features

- 2.1.1 Ideal for Low Current Applications:

- 2.1.2 Quick Operation:

- 2.1.3 Versatility in Control Circuitry:

- 2.2 Common Applications

- 3 Differences – Power Contactors vs. Relays

- 4 Choosing the Right Device

- 5 Get your Contactor from Schneider Electric Thailand

In the electrified landscape of technology and innovation, navigating through the intricate pathways of power contactors and relays emerges as a common yet significant challenge. It’s a territory where professionals, from seasoned engineers to burgeoning hobbyists, find themselves deciphering the complex codes of electrical efficacy, where every choice echoes in the corridors of functionality and safety.

Our expedition into this realm is crafted to be more than an exploration – it’s a journey of enlightenment. We aim to dissect, analyze, and unravel the intricate dance between power contactors and relays. Each section, each insight, is meticulously woven to imbue clarity, offering a lantern in the murky paths of decision-making. In this narrative, the term power contactor isn’t just technical jargon but a character in our story of electrical applications, waiting to reveal its prowess, limitations, and optimal terrains of operation. Your journey to selecting the ideal switching device, be it for an industrial behemoth or a petite, precision-centric task, is about to get illuminated.

Power Contactors

Power contactors are akin to the champions in the arena of electrical switching, designed for prowess, endurance, and optimal performance. Think of them as the heavy-duty machinery that navigates high-power terrains with ease and efficiency, ensuring that operations proceed seamlessly even in demanding environments.

Key Features

The following are the key features of the power contactors:

High Current Rating:

Power contactors are renowned for their ability to manage high currents effortlessly. This feature is akin to a strong backbone, ensuring that the device can withstand and control significant power flows without faltering, making it a reliable choice for applications requiring sturdy performance.

Built-in Overload Protection:

Safety and efficiency intertwine in power contactors thanks to their built-in overload protection. This means they’re designed not just to perform but to safeguard the entire system against power surges and overloads, acting as a sentinel that prevents damage and enhances operational safety.

Suitable for Frequent Switching Operations:

The endurance of power contactors is noteworthy. They are engineered for frequent use, making them the go-to option for applications where switching operations are a common occurrence. Their design minimizes wear and tear, ensuring longevity and consistent performance.

Common Application

These are the common applications of power contactors:

Motor Control Centers:

In the world of motor control, precision, and reliability are king. Power contactors rise to this occasion, offering seamless operation that ensures motors and machinery operate at optimal efficiency, safeguarded against potential overloads.

Heating Systems:

Heating systems demand a switching device that can handle high currents while offering precision. Power contactors fit this bill, ensuring that heating operations are not just efficient but are enveloped in a layer of safety courtesy of their built-in overload protection.

Industrial and Commercial Power Distribution:

In the dynamic landscape of power distribution, power contactors stand as pillars of reliability. Their high current rating and endurance make them an invaluable asset in ensuring that power is distributed efficiently, safely, and reliably across various channels.

In essence, power contactors merge power, safety, and endurance, embodying a trifecta of features that make them a favorite in applications where reliability, safety, and efficiency are paramount.

Relays

Relays are often perceived as the intricate, meticulous artists of the electrical world. They handle lower power tasks with precision and delicacy that ensure optimal function, even in complex scenarios. Where power contactors are the stalwarts of heavy lifting, relays excel in detailed, nuanced operations, ensuring efficacy and reliability.

Key Features

The key features of relays are the following:

Ideal for Low Current Applications:

Relays shine in environments where low current is the norm. Their design and functionality are tailored to excel in settings where precision and quick response are critical, ensuring that even with lower power, performance remains uncompromised and highly efficient.

Quick Operation:

Speed and responsiveness define relays. They are engineered to respond and operate swiftly, making them ideal for applications where timing is crucial. The quick operation ensures that the relay’s tasks, from switching to signaling, are accomplished promptly, enhancing the efficiency of the systems they are integrated into.

Versatility in Control Circuitry:

The adaptability of relays is one of their standout features. They can be integrated into diverse control circuitries, offering a level of flexibility that enables designers and engineers to utilize them in a variety of configurations and settings, thereby optimizing system performance.

Common Applications

Here are the common applications of the relays:

Automation Systems:

In the precision-centric world of automation, relays are invaluable. Their quick operation and adaptability ensure that automated systems respond in real-time, enhancing both the efficiency and effectiveness of automation processes.

Telecommunication Equipment:

The telecommunications landscape demands precision and rapid response. Relays, with their quick operation, ensure that telecommunication equipment functions optimally, facilitating seamless communication flows and ensuring system reliability.

Safety and Monitoring Circuits:

Safety and monitoring are about vigilance and responsiveness. Relays, with their eyes-on-the-price approach, ensure that safety protocols are initiated promptly, and monitoring systems are always on the alert, safeguarding assets and personnel.

In the nuanced dance of electrical operations, relays emerge as the custodians of precision, speed, and adaptability. They aren’t just components; they are strategic assets that elevate the performance, safety, and efficiency of the applications they grace with their presence.

Both power contactors and relays are esteemed members of the electrical switching family, each boasting unique capabilities yet sharing inherent functionalities. In the orchestration of power control, safety, and system efficiency, these devices play pivotal roles, albeit with distinct touches of mastery.

Differences – Power Contactors vs. Relays

The two devices differ in the following points:

Load Capacity:

Power contactors are known for their bravado in handling high power loads. They are the titans in scenarios where power surges are commonplace, ensuring that systems remain unscathed and operational. The electrical contactor price is often justified by this robust capacity, offering value in performance and durability. In contrast, relays are the silent maestros, handling lower loads with precision and efficacy.

Physical Size:

Power contactors, given their heavy-duty nature, are often larger. Whether it’s an AC power contactor or a DC power contactor, the size is tailored to accommodate the robust internal components that stand resilient against high powers. Relays, however, are compact, and designed for intricate, space-sensitive operations where finesse is paramount.

Application Suitability:

Power contactors thrive in environments where the electrical loads are as hefty as the demands for reliability and endurance. They are the unsung heroes in industrial settings, where their price is a mere prelude to the symphony of efficiency and safety they usher. Relays, on the flip side, find their sanctuary in applications requiring swift, precise operations, especially where lower loads are the order of the day.

Performance Metrics

A detailed dissection reveals power contactors as the warriors of high-load, high-frequency environments. Their design, akin to a fortified castle, is built to withstand, deliver, and outlast. However, in the elegant ballet of precision and efficiency under lower loads, relays dance to the limelight, unmatched in their grace and accuracy.

Choosing the Right Device

Embarking on the journey of choosing between these two entails a deep dive into a sea of specifics, where every wave and tide is shaped by unique operational demands and environmental contexts.

Take time to consider the following in choosing the right device:

Load Type and Capacity:

It’s a delicate balance where the scales tilt in favor of power contactors for heavy-duty, high-load environments. Here, even the electrical contactor price fades into the backdrop, overshadowed by the device’s sheer performance and reliability. Relays, however, are the chosen ones for applications characterized by lower loads, where precision and speed are the golden tickets.

Application Environment:

The ambiance of the operation is crucial. AC power contactor options are often the gems in alternating current scenarios, while DC power contactors shine in direct current environments. Relays, with their adaptability, morph gracefully across diverse settings, especially where space and precision are at a premium.

Specific Control Requirements:

Every application sings a unique tune of requirements. While the robustness of power contactors echoes the rhythms of industrial-grade operations, relays compose melodies of precision, suited for intricate, detailed control tasks.

In this intricate dance of choice, understanding the nuances, weighing the scales, and aligning with specific operational narratives paves the path to an enlightened selection, where every dollar spent resonates with value delivered, and every performance metric echoes the symphony of efficiency, safety, and operational excellence.

Navigating the terrains of power contactors and relays is akin to a journey through the diverse landscapes of electrical control and distribution. Each device, with its unique attributes, is tailored for specific scenarios and applications.

As you tread this path, armed with insights and data, remember – the right choice isn’t just about the present but also about the future. It’s a decision that influences performance, safety, and efficiency, not just ticking the boxes of requirements but elevating the entire application to a pinnacle of optimal performance and reliability.

Get your Contactor from Schneider Electric Thailand

Navigating between power contactors and relays is made seamless with Schneider Electric. We understand the intricate demands and challenges you face, and we’re here to offer solutions that are not just innovative but are tailored for excellence.

Discover a range of top-tier contractors, each engineered for performance, safety, and efficiency, at https://www.se.com/th/en/. It’s not just a product; it’s a partnership, a journey into a space where quality meets innovation.

Your insights and experiences in the world of power contactors and relays are invaluable. Join us, explore, and let’s script a narrative of electrical excellence together. Schneider Electric, where your electrical solutions await.