Formlabs Form 3+ Review

- 1 Formlabs Form 3+ Specs

- 1.1 PROS

- 1.2 CONS

- 1.3 Price and Setting

- 1.4 Build

- 1.5 Complementary Items

- 1.6 Controllers and software

- 1.7 How to Set Up?

The Form 3+, one of Formlabs’ best resin-based 3D printers, has superseded the Form 3. In recent years, lower-cost models have developed to compete with Formlabs’ more expensive printers in this 3D printing market. This area has innovated. Even though the Photon Mono X makes SLA printing more affordable, corporations and other organizations that need reliable and high-quality 3D printing still choose the Form 3+. The latest iteration of Formlabs’ industry-leading 3D resin printer improves usability and print speeds while retaining all of its advantages.

Formlabs Form 3+ Specs

| 3D-Printing Technology | Stereolithography |

| Materials Supported | Resin |

| Number of Print Colors | 1 |

| Number of Extruders | 1 |

| Frame Design | Closed |

| Maximum Build Area (HWD) | 7.3 by 5.7 by 5.7 inches |

| Dimensions (HWD) | 20.9 by 15.9 by 14.8 inches |

| Weight | 38.5 lbs |

PROS

- The print quality is superb.

- Comprehensive SLA Workflow Engine

- Almost no emissions during the operation

- You can connect through USB, Wi-Fi, or Ethernet.

- Quick and helpful phone support staff

CONS

- Impossible to erase the printed word

- The resin tray seating procedure causes issues

- Difficulty in getting started with aids

- High amounts of isopropyl alcohol are needed.

Price and Setting

Formlabs originally indicated that the Form 3+ would cost $3,499; however, supply chain issues forced a price increase to $3,750. The original Formlabs printer is still available. Even before the price rise, $3,500 was too much for a printer, especially compared to the Photon Mono X, which costs $500. The Form 3+ can be customized with various add-ons. The $229 Build Platform 2 helps remove items from the build platform. (The Form Cure now costs $750, up $50.)

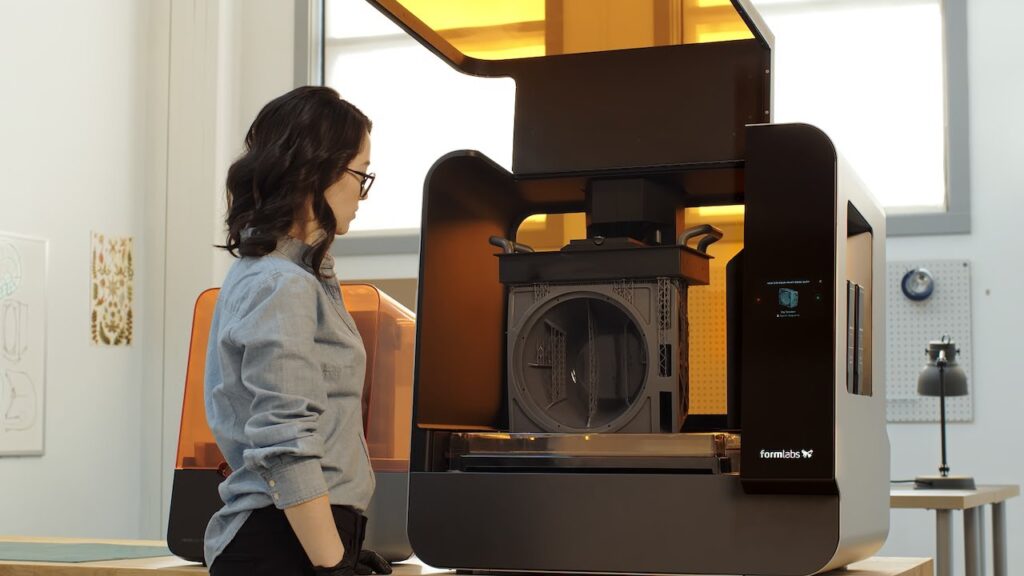

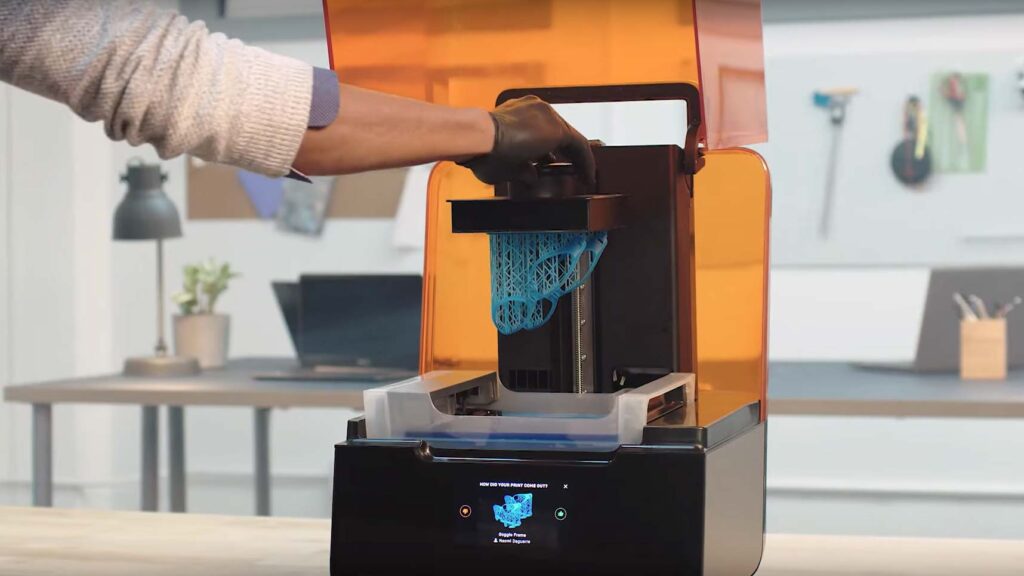

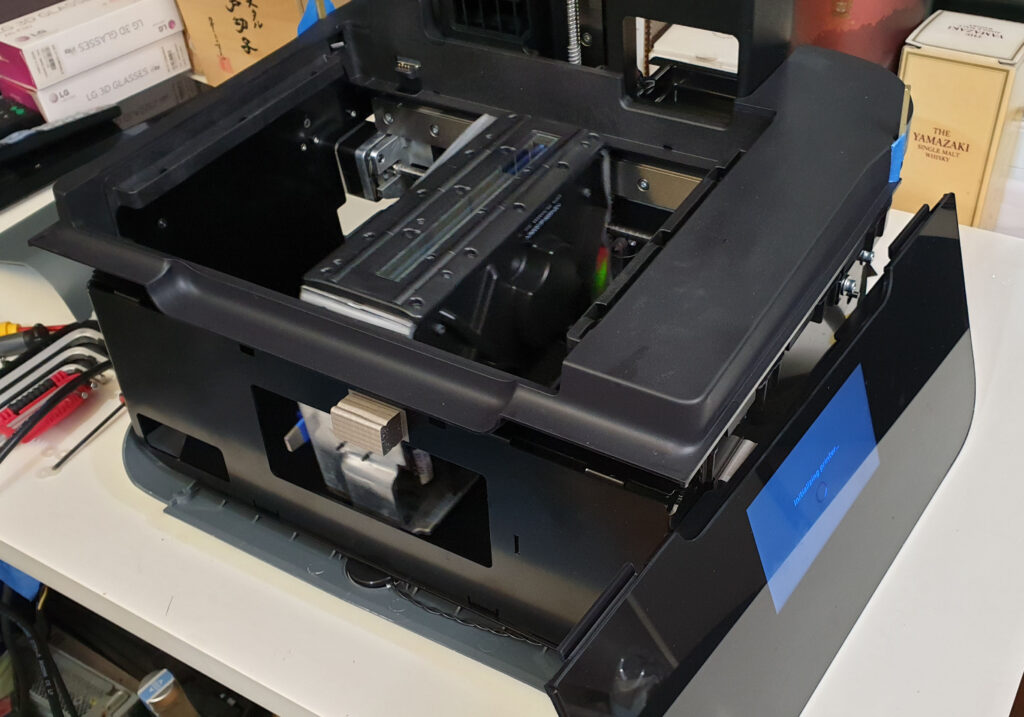

Build

Formlabs describes the Form 3+ as an LFS printer. This printer solidifies resin with a 250 mA UV laser. The Form 3+ has an orange see-through plastic cover that folds up from the front to allow access to the construction area and the same hefty, industrial design as prior Formlabs models. This design came from Form 2.x. The Form 3+’s build area is 5.7 x 5.7 x 7.3 inches or 237 cubic inches, and its layer size is 25 to 300 microns. That is much smaller than most FDM and SLA printers. If you want something bigger, Formlabs’ Form 3L can print things up to 13.2 inches, 7.9 inches, and 11.8 inches, totalling 1,230 cubic inches. The Form 3+’s liftable lid hides a large, easy-to-use touch screen. This screen shows the print job’s status and lets you manage it. Wi-Fi, Ethernet, or USB connections can send print jobs to the Form 3+ printer from a PreForm PC.

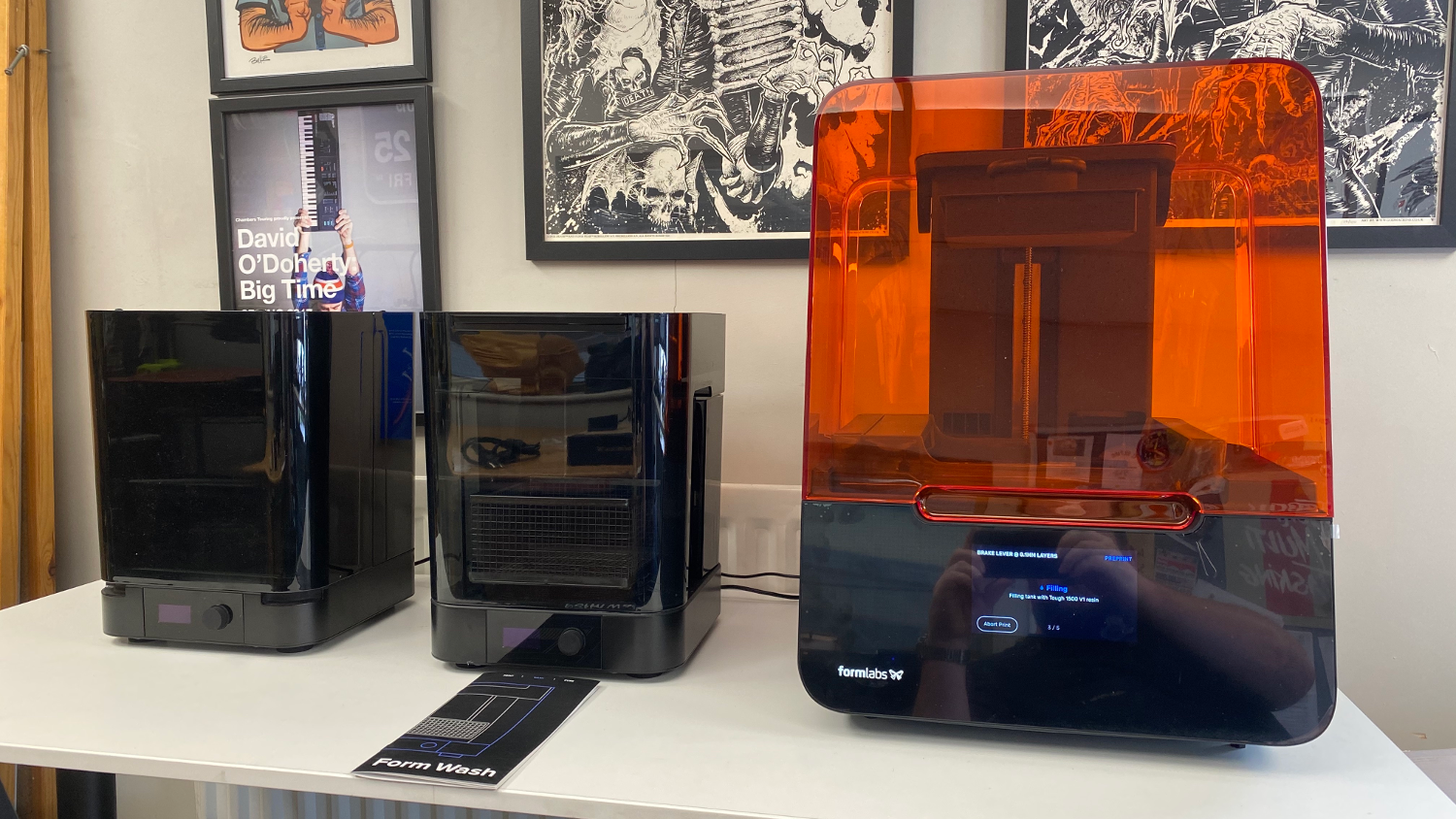

Complementary Items

With a plastic container and UV lamp, you can wash and cure prints without them. But adding these makes the process easier and faster: the Form Wash cleans the print’s crevices with isopropyl alcohol, and the Form Cure heats it while it dries to fix the resin. These steps are needed to clean the print completely. Working together, they may create a whole manufacturing line, from importing the 3D model to printing a ready-to-use print.

Controllers and software

The Form 3+ can be controlled by the touchscreen, PreForm software, or Dashboard internet interface. Form 3+’s touchscreen is huge, bright, and easy to read. From here, you can start and stop printing, setup the printer, and put it to sleep. PreForm, available for free on Windows and Mac, is the main tool for configuring print jobs and managing the printer. This method loads 3D models, aligns them for printing, and generates the Form 3+ print file. A one-touch function does most of the work for you, making it even simpler. The Form 3+ can link to the PreForm app, so the printer knows what resin to use and how to alter print settings. You must press two more buttons before transmitting the file and starting the print job, but it is close to one touch.

How to Set Up?

- Adjust the level of your printer.

- Establish a connection to the network.

- Make sure the printer has the most recent firmware update.

- Insert the consumables, which are the build platform, the resin cartridge, and the resin tank.

- If you need more product assistance, you may get in touch with Formlabs assistance or your authorized reseller.