Injection Molding for Prototyping: Rapid and Cost-Effective Solutions

- 1 Understanding Injection Molding for Prototyping

- 1.1 What is Injection Molding?

- 1.2 The Benefits of Injection Molding for Prototyping

- 1.3 Key Considerations for Choosing Injection Molding for Prototyping

- 2 Rapid Prototyping with Injection Molding

- 2.1 Exploring Rapid Prototyping Techniques

- 2.2 How Injection Molding Enables Rapid Prototyping

- 2.3 Advantages of Rapid Prototyping with Injection Molding

- 3 Cost-Effectiveness of Injection Molding for Prototyping

- 3.1 The Economics of Injection Molding

- 3.2 Cost Savings Compared to Other Prototyping Technique

- 3.3 Factors Influencing the Cost of Injection Molding for Prototyping

- 4 Overcoming Challenges in Injection Molding for Prototyping

- 4.1 Common Challenges in Injection Molding for Prototyping

- 4.2 Strategies for Addressing Challenges and Ensuring Success

- 5 Choosing the Right Injection Molding Partner

- 5.1 Criteria for Selecting an Injection Molding Partner

- 5.2 Evaluating Experience and Expertise

- 5.3 Considering Quality, Cost, and Lead Times

- 6 Conclusion

Are you looking to accelerate your product development process and bring your ideas to life in record time? Look no further than injection molding for prototyping, the game-changing solution that combines rapidity and cost-effectiveness to deliver high-quality injection molded prototypes.

With injection molding, you can unlock a world of possibilities, bringing your designs to reality with precision, speed, and efficiency. Imagine having fully functional prototypes in your hands within days, allowing you to iterate, test, and refine your product concepts with ease.

In this blog post, we will dive deep into the world of injection molding for prototyping, exploring its benefits, discussing key considerations, and unveiling the secrets to achieving rapid and cost-effective solutions. Get ready to revolutionize your product development process and take a leap toward success with injection molding for prototyping.

Understanding Injection Molding for Prototyping

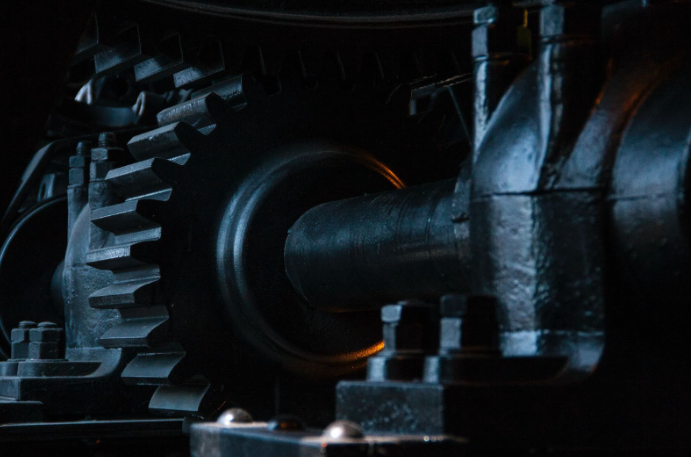

What is Injection Molding?

Injection molding is a versatile and widely used manufacturing process that enables the creation of complex and precise plastic components. It involves injecting molten plastic material into a custom-designed mold under high pressure, allowing it to cool and solidify into the desired shape. This method is highly efficient, producing injection molded prototypes that accurately reflect the final product’s characteristics. By utilizing intricate molds and advanced machinery, injection molding can achieve intricate geometries, fine details, and exceptional dimensional accuracy. It is a preferred choice for mass production due to its cost-effectiveness and scalability.

The Benefits of Injection Molding for Prototyping

Injection molding offers numerous advantages for prototyping. Firstly, it enables the production of prototypes with excellent dimensional accuracy, replicating the desired specifications of the final product. Additionally, injection molding provides a wide range of material options, allowing designers to select the most suitable material for their prototypes. Moreover, this method allows for high repeatability, ensuring consistent quality across multiple prototypes.

Key Considerations for Choosing Injection Molding for Prototyping

When deciding to use injection molding for prototyping, several factors should be considered. These include the complexity of the design, the desired material properties, the required quantity of prototypes, and the time constraints of the project. It is important to evaluate these factors to determine if injection molding aligns with the specific needs of the prototyping process.

Rapid Prototyping with Injection Molding

Exploring Rapid Prototyping Techniques

Rapid prototyping is an iterative design process that accelerates product development by quickly creating functional prototypes. It allows for rapid feedback loops, enabling designers to make iterative improvements and refine their designs efficiently. Injection molding serves as an ideal method for rapid prototyping due to its ability to produce high-quality and accurate prototypes with short lead times.

How Injection Molding Enables Rapid Prototyping

Injection molding’s speed and efficiency make it suitable for rapid prototyping. The process enables the production of multiple prototypes simultaneously, reducing the time required to create and evaluate designs. Moreover, injection molding allows for the production of fully functional prototypes, facilitating comprehensive testing and validation of the design’s performance.

Advantages of Rapid Prototyping with Injection Molding

Rapid prototyping with injection molding offers several advantages. It enables designers to identify design flaws and make necessary modifications early in the development process, reducing the risk of costly errors in later stages. Additionally, it enhances collaboration among team members, as stakeholders can physically interact with prototypes, providing valuable insights and feedback. The speed of injection molding for rapid prototyping also contributes to faster time-to-market, giving businesses a competitive edge.

Cost-Effectiveness of Injection Molding for Prototyping

The Economics of Injection Molding

Injection molding offers cost-effective solutions for prototyping due to its efficiency and scalability. Although upfront tooling costs are involved, injection molding becomes economically advantageous when multiple prototypes or high volumes of parts are required. The cost per unit decreases as the quantity increases, making it a viable option for both small-scale and large-scale production.

Cost Savings Compared to Other Prototyping Technique

In comparison to other prototyping techniques, such as CNC machining or additive manufacturing, injection molding can provide substantial cost savings. CNC machining, while suitable for small quantities, becomes expensive as production volumes increase. Similarly, additive manufacturing techniques like 3D printing can be costlier per unit, especially when using high-performance materials. Injection molding’s ability to produce large quantities of prototypes with minimal material waste contributes to its cost-effectiveness.

Factors Influencing the Cost of Injection Molding for Prototyping

Several factors influence the cost of injection molding for prototyping. These include the complexity of the part design, the choice of materials, the size and intricacy of the mold, and the number of prototypes required. Considering these factors and optimizing the design for manufacturability can help reduce costs while maintaining the desired quality and functionality.

Overcoming Challenges in Injection Molding for Prototyping

Common Challenges in Injection Molding for Prototyping

Despite its many advantages, injection molding for prototyping can present certain challenges. These challenges include managing design complexity, achieving moldability for intricate designs, and ensuring accurate replication of the desired features. Understanding and addressing these challenges are key to successful injection molding for prototyping.

Strategies for Addressing Challenges and Ensuring Success

To overcome the challenges in injection molding for prototyping, several strategies can be implemented. These strategies include conducting thorough design reviews, collaborating closely with mold designers and manufacturers, utilizing advanced simulation tools for mold flow analysis, and leveraging the expertise of injection molding professionals. By addressing challenges proactively and implementing appropriate strategies, successful outcomes can be achieved in the prototyping process.

Choosing the Right Injection Molding Partner

Criteria for Selecting an Injection Molding Partner

Choosing the right injection molding partner is crucial to ensure successful prototyping. Several criteria should be considered, including the partner’s experience and expertise in prototyping, their track record in delivering high-quality prototypes, their ability to handle complex designs, their equipment and technology capabilities, and their commitment to customer satisfaction.

Evaluating Experience and Expertise

An injection molding partner with extensive experience in prototyping brings valuable knowledge and insights to the table. Evaluating their past projects, industry reputation, and expertise in working with different materials and designs helps in selecting a partner who can meet the specific requirements of the prototyping process.

Considering Quality, Cost, and Lead Times

The quality of prototypes, cost-effectiveness, and adherence to lead times are critical factors in choosing an injection molding partner. Assessing their quality control processes, cost structure, and commitment to meeting project deadlines ensures that the chosen partner can deliver high-quality prototypes within the desired timeframe and budget.

Conclusion

Injection molding is a rapid and cost-effective solution for prototyping in product development. By understanding the intricacies of injection molding, leveraging rapid prototyping techniques, optimizing cost-effectiveness, and overcoming challenges, designers can harness the full potential of injection molding for successful prototyping. Selecting the right injection molding partner further enhances the prototyping process, facilitating the development of innovative and market-ready products. Through the utilization of injection molding, designers can propel their product development journey with confidence, knowing they have embraced a powerful tool that enables rapid iteration, cost optimization, and ultimately, successful product launches.