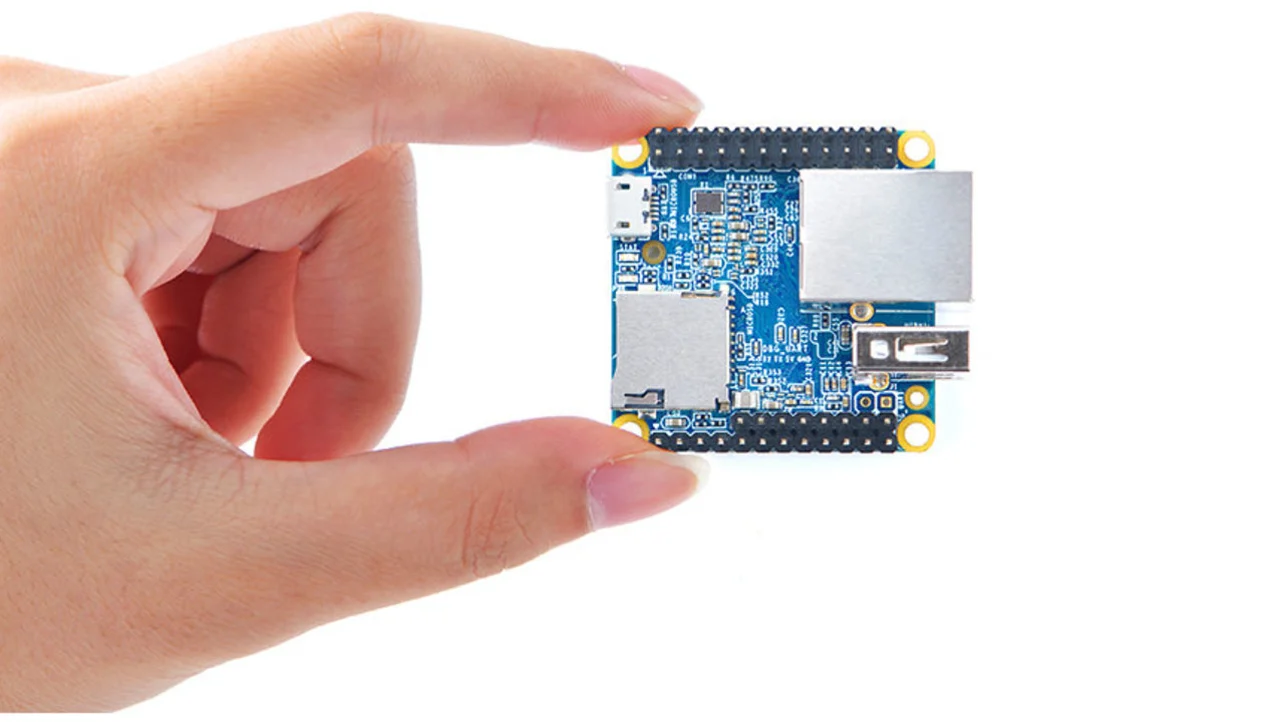

Tiny Single Board Computer (SBC) as a Rapid Prototyping and Development Platform

The Internet of Things (IoT) is one of the most promising technologies in recent years. It has brought unprecedented opportunities for businesses in all industries to harness the power of data and use it to drive better business results.

With IoT and an influx of data came challenges with processing and analyzing data, managing communications and interactions, and remote monitoring capabilities.

Developers sought new solutions to address these challenges, including single-board computers (SBCs) as a foundation of design. During high-volume production, however, irreversible flaws and problems can impact deployment and time to market.

Prototyping solves these problems. With an SBC as a rapid prototype and development platform, developers can test proof of concept and tweak designs for better success before they enter into full-scale production.

Understanding Rapid Prototyping

Rapid prototyping is used to create a sample of a product before full-scale production. IoT development starts with the hardware, then the software, and then the firmware. Hardware and software designs and components need to be cohesive for full functionality.

Without this inherent functionality, developers can struggle to find the right components, often setting off chain reactions of having to tweak more and more design aspects, build again, rebuild, and on and on until they run out of time and budget.

Hardware is a good starting point and serves as a foundation for the rest of the product. As long as the development board functions as it should, software and firmware are more accessible and can be integrated successfully.

Some developers build hardware and software simultaneously, adding, removing, and tweaking components until they get the finished product they want. As they make these changes, the software and hardware components need to be tested.

In addition, many teams work with remote teams. If the team members involved in the project are a great distance from each other, engineers need their prototype board to work on their aspect of the project. Each board will need to be made, purchased, and shipped to each member of the team, adding unnecessary expenses and time to the project.

Of course, boards can be printed with a shared design, but that means that all members of the team have to have a 3D printer and time to create the design. This may be cheaper and a little faster than buying and shipping prototypes, but it still impacts the project.

Ready-made SBCs, such as i.MX 8 single-board computers (SBC) can solve the problem. Much cheaper than a specially made prototype, these boards and components can be purchased and used by all team members, often in their own location. They also require no additional time or design efforts.

How Prototyping Benefits IoT Development

Rapid prototypes are often regarded as cheap and low-quality, likely due to how quickly they’re produced. Developers can leave out essential design features in the process, creating more problems and time than they would if they chose a specially-made prototype.

This couldn’t be further from the truth. Rapid prototyping is affordable, but it’s not low-quality. Using a rapid prototype gives developers flexibility and creative freedom to evaluate and fine-tune a design at any stage of the process, collaborate with team members, and optimize the design for a better final product.

Developers can also use design thinking to explore different design options individually with A/B testing and collect real-time feedback. They can also collaborate with the full team, brainstorm, and workshop ideas until they achieve the desired result.

Prototyping is also much faster than specially made solutions, reducing time to market. Many people intend to verify the design before total production to save time. Still, a flaw in the design that makes it to production adds incredible delays and money to the process. A prototype ensures the design is optimized and functional before it proceeds to total production.

Benefits of Single Board Computers

An SBC, such as the i.MX 6 is a complete and functional computer that has a microprocessor, input/output (I/O) functions, memory, and other components that are found in conventional computers. RAM can be included at the preferred amount.

Personal computers and supercomputer networks are complex, so it may seem counterintuitive to invest in a simple device. However, there’s elegance to the simplicity of SBCs—these boards are often used in smartphones, tablets, and other consumer electronics, as well as IoT devices.

Thanks to their stripped-down design, SBCs are also prone to fewer problems than complex computers. They aren’t as vulnerable to downtime, mechanical failures, or other flaws that can significantly impact processes. With this benefit, SBCs are often used for critical systems like missile guidance systems, traffic light controllers, medical devices, and anti-lock braking and stability control systems.

Ultimately, SBCs are reliable, which is necessary for IoT devices.

Choosing an SBC for Rapid Prototyping and Development

Choosing an SBC for rapid prototyping depends on the requirements and specifications of the project, which should guide the components and desired functionality. Board compatibility is designed alongside software and firmware.

IoT boards also require connectivity. These devices need robust connectivity to perform as intended, so the board must support the level of connectivity necessary for proof of concept. Options for Wi-Fi, Bluetooth, and Ethernet are vital.

The peripherals for the board features are also vital. SBCs have near-limitless configuration options and scalability, so it’s essential to choose the best features at the start and address project specifications.

Some of these may include pin-outs for pulse width modulation or buses for serial protocols like SPI or I2C. USB and HDMI ports should also be considered. Keep the overall project needs in mind and consider peripherals that may be necessary for its specifications.

CAD format, KiCAD design files, and Gerber files are helpful in outlining and archiving the final design for full-scale production.

Rapid Prototyping for Project Success

Ready-made SBCs are the perfect platform for proof of concept and rapid prototypes before moving to full-scale production. Many SBCs, including i.MX 6 single-board computers (SBC), come with basic MCU and wireless components that allow the prototype to move into production after testing, boosting the time-to-market and efficiency of remote, collaborative teams.