Transforming Manufacturing Processes: The Integration of Tech Equipment in Industries

The integration of tech equipment is revolutionizing manufacturing processes across industries. Traditional manufacturing techniques are changing due to cutting-edge technology like the Internet of Things (IoT), robots, automation, and data analytics. These developments increase operational effectiveness, decrease human error and maximize resource use. By automating repetitive tasks, tech equipment like that found at jsproputec.com frees up human resources for more complex and creative roles, resulting in increased productivity and higher-quality products.

Embracing digital transformation empowers industries to stay competitive in a rapidly evolving global market. However, successful implementation requires careful planning, workforce upskilling, and addressing potential challenges. This will ensure a seamless transition toward a tech-enabled future.

The Integration of Tech Equipment in Industries

This article will touch on the various cutting-edge technologies that are transforming traditional manufacturing techniques and close by looking at how this new tech can be successfully integrated into an existing industry.

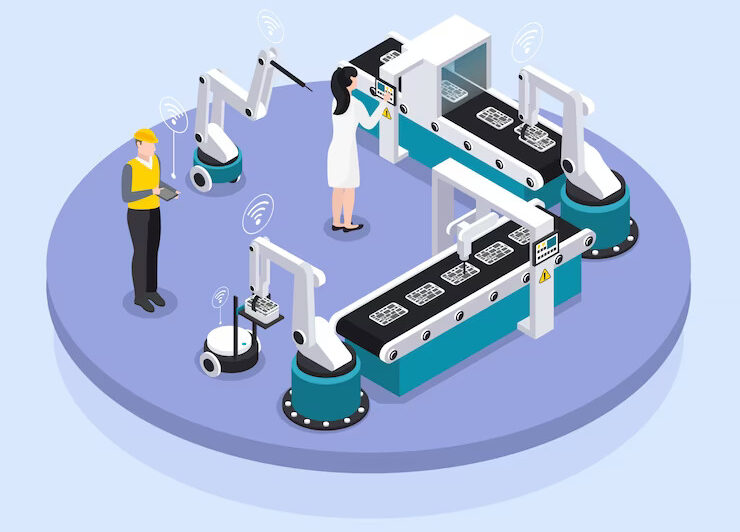

The IoT and smart factory integration

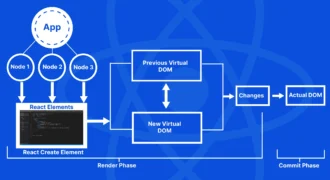

The convergence of the IoT and smart factory concepts is driving a paradigm shift in manufacturing. By leveraging interconnected devices, machines and sensors, industries can create intelligent ecosystems that facilitate real-time data sharing and decision-making. IoT-enabled smart factories optimize production processes through predictive maintenance, remote monitoring and supply chain visibility.

This connectivity enhances efficiency, reduces downtime and ensures just-in-time operations. Smart factory integration enables streamlined production, cost savings and improved overall performance. However, cybersecurity and data privacy must be carefully addressed to safeguard against new threats and vulnerabilities.

Robotics and automation solutions

Robotics and automation have emerged as transformative solutions in modern manufacturing. Robots perform repetitive and hazardous tasks with unparalleled precision, reducing human intervention and the associated risks. By optimizing production lines, robots enhance efficiency, accelerate cycle times and minimize errors, resulting in consistent product quality.

These technologies offer the flexibility to adapt to changing demands and enable mass customization. While robotics enhance productivity, human workers play a vital role in programming, maintenance and problem-solving. Successful integration requires collaboration between humans and machines to create a harmonious and productive work environment.

Data analytics and predictive maintenance

Data analytics and predictive maintenance have become crucial components in industrial operations. By collecting and analyzing vast amounts of data from tech equipment, industries gain valuable insights into equipment performance, production trends and potential bottlenecks.

Predictive maintenance allows proactive identification of equipment issues, reducing unplanned downtime and minimizing maintenance costs. Real-time data analytics also offer opportunities for continuous process improvement and optimization.

Embracing data-driven decision-making enables industries to maximize equipment efficiency. They also extend the lifespan of critical assets and maintain a competitive edge in the market.

Strategies for successfully integrating tech equipment in industries

While integrating tech equipment in industries promises significant benefits, several challenges must be addressed for successful implementation. One major hurdle is the need for a skilled workforce capable of operating and maintaining advanced technologies. Upskilling and retraining programs are essential to equip employees with the necessary expertise.

Cost considerations can also pose challenges, particularly for small and medium-sized enterprises. Proper planning, phased implementation and government support can alleviate these financial burdens.

Cybersecurity is another critical concern, necessitating robust measures to protect sensitive data and prevent potential breaches.

By adopting a comprehensive approach, industries can overcome challenges and unlock the full potential of tech equipment integration for transformative manufacturing processes.