Six Key Benefits of Vacuum Casting

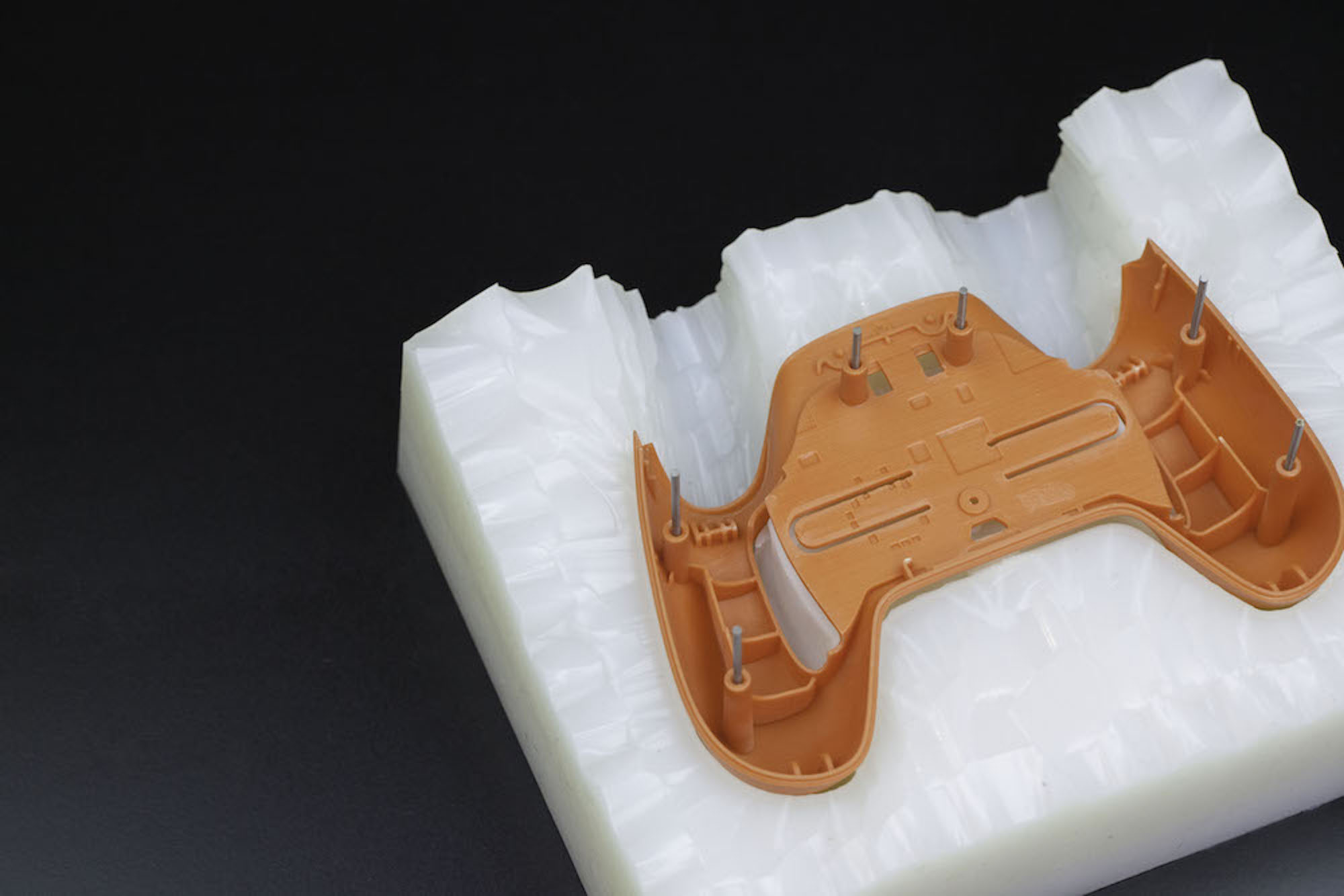

Silicone molds are used in vacuum casting manufacturing to produce exact duplicates of items. Because of its high accuracy and short turnaround time, it’s a preferred option for making plastic parts in small quantities. While 3D printing is relatively new, vacuum casting is an established process for prototyping that may not seem as glamorous or high-tech as additive manufacturing. Vacuum casting in polyurethane resin is still helpful for creating high-caliber prototypes.

Perfect Finished Products

When you employ options like rapid prototyping services, ensure they offer information regarding the final product. It is crucial to give greater attention to all the details regarding the product. The finalized product gets a look that resembles the original product. You need to give proper consideration to all the essential things. Even when dealing with the original product, you must avoid complex methods. Whenever you need to get authentic, you must consider the entire vacuum casting process. Only then might you get multiple benefits.

Superior Material Simulation

When you utilize this season to use a silicone mold, it provides information about the end result. Ensure that you pay special attention to all of the product’s details. The finalized product is displayed with a similar appearance to the original product. You must give thorough consideration that takes into account all of the relevant factors. Even when dealing with the original product, complex approaches should be avoided. If you want to acquire an original over, you must evaluate the entire vacuum casting procedure. Only then will you be able to reap multiple benefits.

Perfect part-to-part consistency

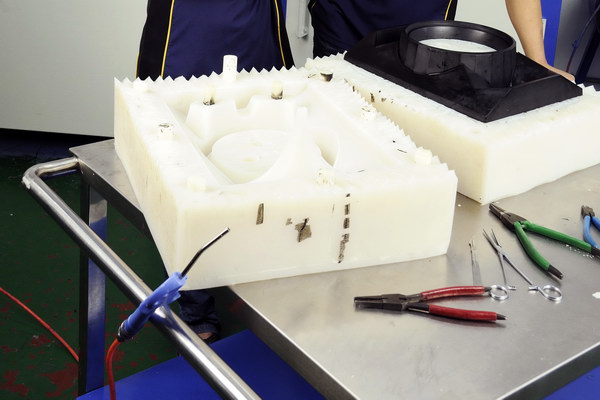

The casting procedure is extremely precise, mold wear is nearly non-existent, and hand-finishing is low. This means almost no part-to-part variance can be useful when assembling with other parts and testing. If the mold reaches the end of its useful life and a replacement is needed, another master pattern must be 3D-produced. The accuracy of the master design is excellent when using the SLA method; therefore, castings from molds made from various masters should be identifiable.

Fantastic surface treatment

After 3D printing or CNC machining, the master model gets its surface finished to the customer’s specifications. The cured silicone mold can be subjected to a comprehensive surface reduction to the standard model. This one-time surface treatment saves several dollars and hours on subsequent copies.

Perfect for multiple phases in product development

Because vacuum casting is such a versatile technique, it is employed at nearly every stage of a product development endeavor where many parts are required. Idea creation, visual & functional prototypes, handling tests, performance evaluation (e.g., airflow), assembly system idea development, assembly line trials, and marketing – including exhibitions, presentations to supporters, focus groups, and promotional photography – are all part of this.

Low production cost

Aluminum is a more expensive substance than silicone—liquid silicone costs about 45% more than aluminum under the same volume conditions. CNC machining is one subtractive manufacturing technique that cuts the aluminum block till it has an optimum mold cavity. Another material expense is the cut material. Prior to CNC processing, mass calculation and setup are performed. All of these preparations raise labor costs. Vacuum casting duplicates items with minimal material waste. It is better for the environment.

Vacuum casting provided by agencies like rapid prototyping services is a cost-effective and precise method of producing plastic parts in small quantities without losing quality or detail. It’s great for rapid prototyping, testing new designs, and creating small batches with complicated features.