Navigating the Realm of Precision Machining: Unraveling its Definition, Advantages, and Potential Applications

- 1 A Deep Dive into Precision Machining

- 2 Advantages of Precision Machining

- 3 Unraveling the Applications of Precision Machining

- 4 Expanding the Boundaries of Precision Machining

- 4.1 Telecommunication:

- 4.2 Electronics:

- 4.3 Energy:

- 5 The Indispensable Role of Precision Machining in Manufacturing

- 5.1 Driving Quality and Consistency

- 5.2 Responding to Customization Needs

- 5.3 The Future of Precision Machining

- 6 Conclusion

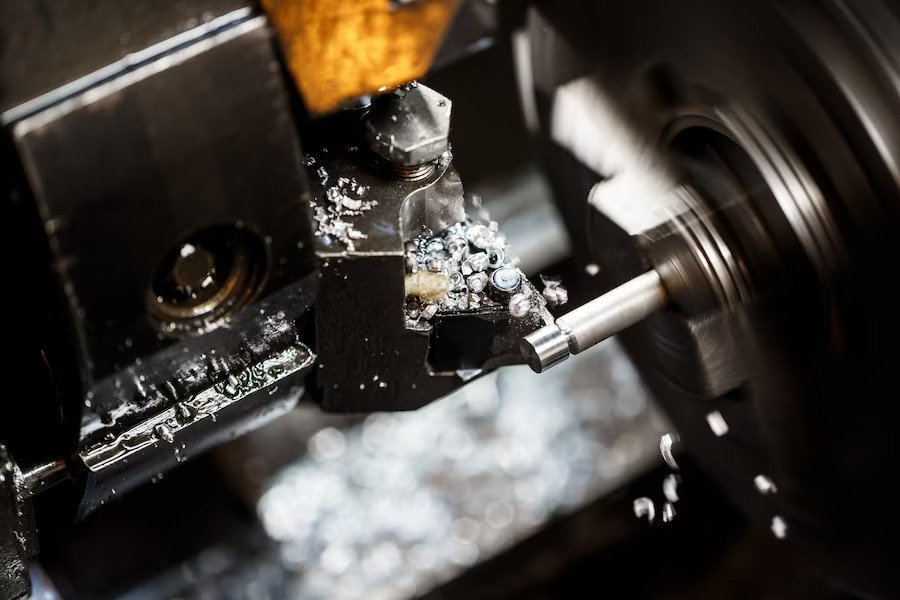

Stepping into the vast and ever-evolving landscape of manufacturing technologies, one might find themselves lost in a sea of terminologies and processes. Yet, amidst this complexity, there’s a particular term that consistently stands out, especially in the realm of high-tech production: Precision Machining.

A Deep Dive into Precision Machining

Precision Machining, a term often used interchangeably with Computer Numerical Control (CNC) Machining, signifies a manufacturing process that involves the removal of material from a workpiece. The operation is guided by a highly detailed blueprint (often digital), ensuring exact precision. This precision in fabrication is the essence of the process and is achieved through the utilization of advanced CNC machines such as mills, lathes, grinders, or routers, which can follow complex, three-dimensional designs with incredible accuracy.

Advantages of Precision Machining

There’s a multitude of reasons behind the increasing popularity of CNC Machining in various industries. The benefits go beyond the sheer accuracy that the name implies, offering value on multiple fronts.

Before delving into the specifics, it’s worth noting that the advantages of Precision Machining often intersect and reinforce each other, resulting in a powerful blend of performance, efficiency, and quality.

Efficiency and Speed: Precision Machining allows for the mass production of complex

CNC machining parts with incredible speed: Given that the process is automated, it reduces the time taken from design to production, accelerating the manufacturing cycle.

Consistency and Accuracy: With a high level of control over the production process, Precision Machining guarantees the production of identical parts with extremely close tolerances. This consistency is crucial in industries where precision and accuracy are paramount.

Versatility: Precision Machining can be used with a variety of materials, including metal, plastic, glass, and ceramics, providing manufacturers with flexibility in material selection.

Unraveling the Applications of Precision Machining

Precision Machining has a broad spectrum of applications- The inherent precision and consistency of this manufacturing process make it an ideal choice in industries where high levels of accuracy and repeatability are essential.

Aerospace Industry: The aerospace industry relies heavily on Precision Machining. The manufacturing of complex components that make up an aircraft, such as engine parts or structural components, requires a high level of precision and consistency, which Precision Machining ensures.

Medical Industry: Similarly, in the medical industry, Precision Machining is used to produce highly precise medical devices and components, like implants, surgical instruments, and diagnostic equipment.

Automotive Industry: From engine components to intricate parts of a vehicle’s braking system, Precision Machining is widely used in the automotive industry for its accuracy and efficiency.

Expanding the Boundaries of Precision Machining

The scope of Precision Machining is not limited to the aforementioned industries. As a matter of fact, its utilization is continually expanding, driven by the needs of emerging technologies and the relentless pursuit of precision and efficiency.

Telecommunication:

This industry is becoming increasingly dependent on Precision Machining for creating minuscule and precise components used in communication devices and network equipment.

Electronics:

Precision Machining is heavily used in the electronics industry to manufacture parts like circuit boards, connectors, and casings with strict dimensional tolerances.

Energy:

In the energy sector, particularly in renewable energy technologies like wind turbines and solar panels, Precision Machining contributes to enhancing efficiency and durability.

The Indispensable Role of Precision Machining in Manufacturing

Precision Machining has grown from a niche sector to an integral part of modern manufacturing processes. The complexity of designs, the demand for high precision, and the need for mass production at an accelerated pace has mandated the use of methods like Precision Machining.

Driving Quality and Consistency

Precision Machining ensures that each part produced is exactly like the last. This consistency is paramount in industries where discrepancies can lead to system failures. Moreover, the superior quality of products manufactured through Precision Machining can lead to longer product life cycles, reducing the overall costs in the long run.

Responding to Customization Needs

The automated and precise nature of machining allows manufacturers to respond to the growing demand for customization. It enables the production of complex, custom parts on a large scale, a task that would be time-consuming and potentially inaccurate if performed manually.

The Future of Precision Machining

As we move into an era of Industry 4.0, characterized by the integration of automation and data exchange in manufacturing technologies, Precision Machining is poised to take on an even more significant role. Its evolution is expected to be driven by advancements in artificial intelligence, machine learning, and materials science, leading to increased automation, improved efficiency, and enhanced capabilities.

Conclusion

To sum up, Precision Machining has truly revolutionized the manufacturing landscape, bringing forth unparalleled precision, efficiency, and consistency. The broad range of its applications underlines its importance in multiple sectors, from aerospace to medical to electronics, and its potential contributions to emerging industries. As we march forward into an era of increased automation and digitalization, Precision Machining stands as a pillar of advanced manufacturing, promising to drive innovation, productivity, and quality in the years to come. It is not just a manufacturing technique; it is an essential cog in the wheel of technological progress.