Why AWB Tracking is Vital for International Business Shipping

- 1 How AWB Tracking Fits into Air-freight Shipping

- 1.1 Why AWB Tracking Matters for Your Business

- 1.1.1 1. Enhanced Visibility and Supply-chain Control

- 1.1.2 2. Risk Mitigation and Cost Reduction

- 1.1.3 3. Customer Service and Brand Reliability

- 1.1.4 4. Operational Efficiency and Inventory Optimization

- 1.1.5 5. Compliance and Claim-handling Support

- 1.2 Best Practices for Implementing AWB Tracking in Your Business

- 1.2.1 1. Partner with Carriers/Freight Forwarders that Support Real-time Tracking and API Access

- 1.2.2 2. Capture and Share the AWB Number Immediately

- 1.2.3 3. Define Key Shipment Milestones and Exceptions

- 1.2.4 4. Use Tracking Data for Analytics

- 1.2.5 5. Align Internal Operations with Tracking Updates

- 1.2.6 6. Consider Digital/Documentation Readiness (e-AWB)

- 1.2.7 7. Educate Stakeholders

- 2 Taking your International Shipping to the Next Level

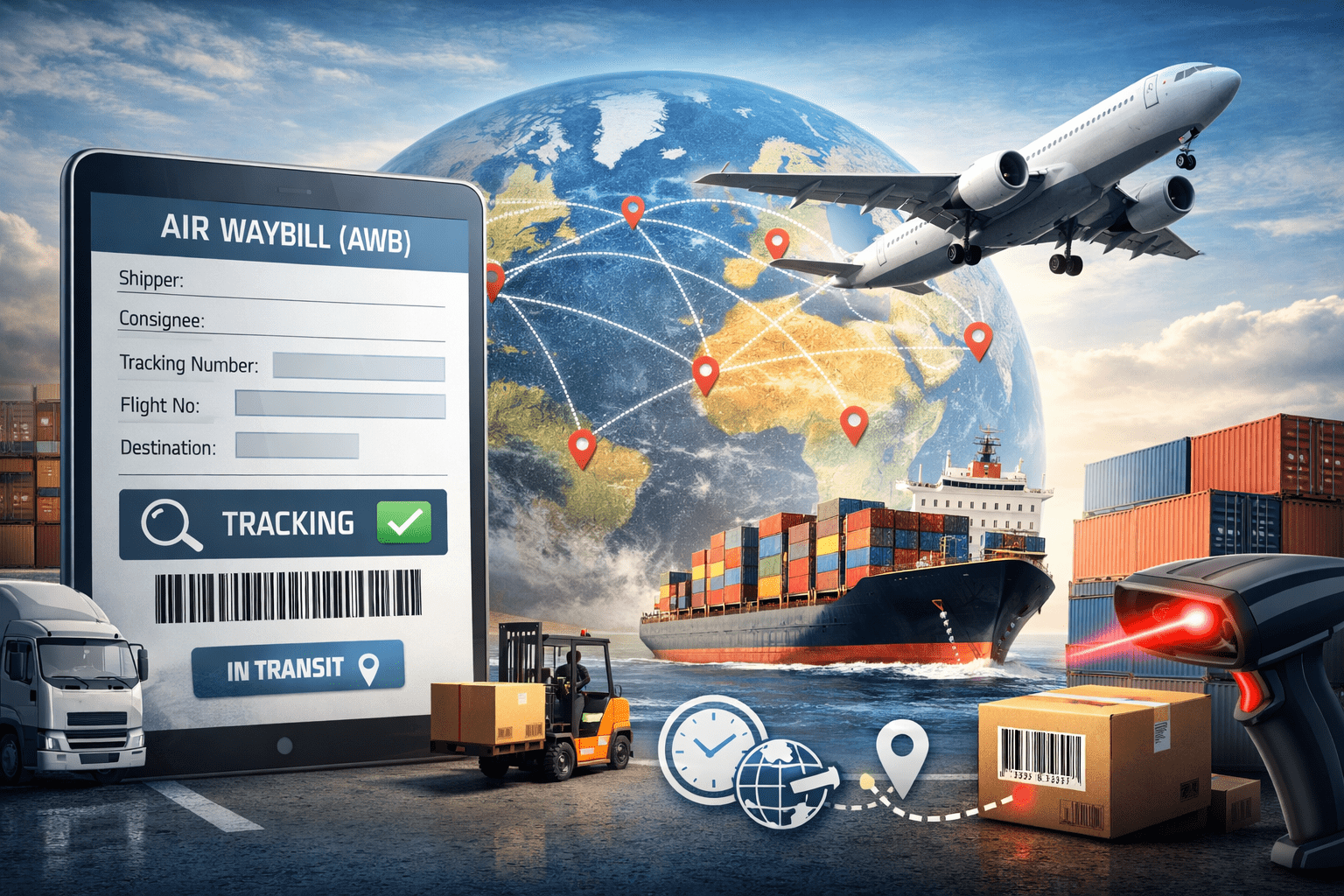

Global shipping is moving faster than ever before, and businesses must stay ahead of logistics variables to remain competitive. One fundamental tool in this arena is ‘Air Waybill (AWB) tracking’, which offers precise visibility into air-freight consignments and helps control costs, delays, and customer-service risks.

Understanding how AWB tracking works gives clear insight into your shipping process and how it benefits both B2B and B2C supply chains. Putting these insights into practice helps your business gain reliability and growth. Let’s look at its role and advantages.

How AWB Tracking Fits into Air-freight Shipping

An AWB serves as the contract of carriage and receipt of goods for air cargo. Each AWB carries a unique identifier (typically 11 digits) that enables the shipper, carrier, and consignee to monitor a shipment in transit.

When you apply AWB tracking in your operations, you gain real-time status updates from origin to destination. For example, you can determine when the goods leave the origin airport, clear customs, arrive at the hub, and are ready for delivery. These data points are especially valuable when shipping internationally.

Why AWB Tracking Matters for Your Business

Knowing where your shipment is at any moment is vital in international air freight. With effective AWB tracking, you gain immediate visibility and clarity, enabling smarter decisions, proactive responses, and improved trust among customers and partners.

1. Enhanced Visibility and Supply-chain Control

For B2B shipments, for example, components arriving in manufacturing visibility reduces idle time, cuts disruptions in production lines, and improves forecasting. When it comes to B2C operations such as direct‑to‑consumer goods, this visibility delivers clearer customer updates, fewer “Where’s my shipment?” queries, and strengthens brand trust.

2. Risk Mitigation and Cost Reduction

International shipping carries many risks, including routing changes, airport congestion, customs holds, cargo misrouting, and even theft. When you have AWB tracking, you can detect issues earlier. For example, you might receive an alert that cargo is delayed at a transit airport, allowing you to reroute or inform the customer.

Tracking also helps avoid hidden costs, such as demurrage or storage charges at airports, penalties for late inventory arrival, or extra labor costs from unexpected handling. From a business perspective, less surprise means better margin control.

3. Customer Service and Brand Reliability

In a globalized supply chain, the expectation of transparency has become standard. Whether you are shipping finished goods to a retail partner (B2B) or sending a package to a consumer (B2C), the ability to tell “the shipment is here/in-flight/arrived” improves stakeholder trust.

When you integrate AWB tracking into your client communications, sharing links or alerts, you reduce inbound tracking queries, enhance perceived professionalism, and strengthen customer loyalty.

4. Operational Efficiency and Inventory Optimization

With accurate tracking, you know when inventory will hit a hub or warehouse. That allows better scheduling of manpower, staging space, and final-mile logistics. When you know arrival times more precisely, you reduce safety-stock levels, avoid over-buffering, and commit less capital to standing inventory.

In both B2B and B2C contexts, this drives cost savings (less warehousing, fewer excess goods) and faster fulfilment.

5. Compliance and Claim-handling Support

The AWB document carries detailed cargo information (weight, description, origin, destination), which is also used for customs and regulatory clearances. By tying AWB tracking data to shipments, you create audit-capable records.

In case of damage, misrouting, or loss occurs, AWB tracking acts as evidence of the shipment path and statuses. This information helps support insurance claims, carrier liability discussions, and forensic logistics analysis.

Best Practices for Implementing AWB Tracking in Your Business

Implementing AWB tracking properly gives you more than shipment visibility. Clear processes and smart use of tracking data unlock operational efficiency, cost savings, and better supply‑chain control.

1. Partner with Carriers/Freight Forwarders that Support Real-time Tracking and API Access

Make sure your logistics provider delivers timely updates and integrates with your systems. Many have portals or APIs for AWB tracking.

2. Capture and Share the AWB Number Immediately

As soon as the cargo is booked and handed over, ensure the AWB number is communicated internally (logistics team, warehouse, customer service) and externally (buyer, recipient).

3. Define Key Shipment Milestones and Exceptions

Identify major checkpoints (departure, arrival at hub, customs clearance, final delivery) and define thresholds (e.g., if delay > X hours at hub). Set alert mechanisms so you can act proactively when tracking shows deviations.

4. Use Tracking Data for Analytics

Over time, compile transit times by origin–destination, delay frequency by carrier, and hub performance. Leverage AWB tracking logs to benchmark carriers and routes, optimize partner choices, and negotiate service levels.

5. Align Internal Operations with Tracking Updates

Warehouse teams and transport teams should schedule based on tracking status, unloading labor, staging space, and onward transport. For B2C, customer service teams should be ready to communicate updates as changes are tracked.

6. Consider Digital/Documentation Readiness (e-AWB)

Many carriers now use the electronic version of AWB (e-AWB), which reduces paperwork, speeds up processing, and improves tracking integrity.

7. Educate Stakeholders

Clients, logistics staff, and partners should know how to use the tracking portal and what statuses mean. Clear communication improves the value derived from AWB tracking.

Taking your International Shipping to the Next Level

Integrating AWB tracking into your international shipping workflow is not a luxury; it is a strategic capability. It gives you transparency, control, cost efficiency, and improves customer experience, whether you work B2B or B2C.

With strong AWB tracking practices, you can manage delays proactively, optimize inventory, support compliance, and build stronger logistics partnerships. Logistics service providers like DTDC offer full-chain tracking capabilities and can help you implement AWB tracking standards across your operations.