The Impact of Electrostatic Discharge on Sensitive Electronic Components

- 1 Generation of Static Electricity

- 2 Effects of ESD on Electronic Components

- 2.1 Physical Damage

- 2.2 Performance Degradation

- 2.3 Reduced Reliability

- 2.4 Typical ESD Impact Scenarios in Real Applications

- 3 Damage Mechanisms of Electrostatic Discharge

- 3.1 Thermal Effects

- 3.2 Electrical Effects

- 3.3 Mechanical Effects

- 3.4 Common ESD Failure Modes in IC Chips

- 3.5 Gate Oxide Breakdown

- 3.6 Junction Burnout

- 3.7 Metal Interconnect Melting

- 3.8 Latent ESD Damage

- 4 Prevention and Protection Measures

- 5 Conclusion

In the electronics industry, electrostatic discharge (ESD) is a common yet highly destructive phenomenon. It can be generated by human movement, equipment operation, or environmental changes. As electronic technology continues to evolve toward higher integration, smaller geometries, and lower operating voltages, the impact of electrostatic discharge on electronic components has become increasingly significant.

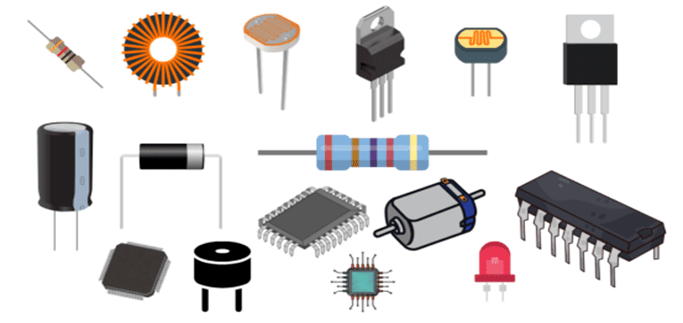

Sensitive electronic components—such as IC chips, microprocessors, memory devices, and sensors—feature tiny structures and thin insulating layers, making them particularly vulnerable to ESD events. Even a brief electrostatic discharge can cause permanent damage to an integrated circuit (IC chip), ultimately affecting the performance, reliability, and lifespan of the entire electronic system.

Generation of Static Electricity

Static electricity is generated by the accumulation of electric charge on the surface of materials. In dry environments, friction between the human body and clothing, as well as repeated contact and separation of materials during equipment operation, can easily lead to electrostatic buildup.

In electronic manufacturing and assembly processes, insulating materials such as plastics and rubber are widely used. These materials prevent charges from dissipating quickly, increasing the risk of ESD. As a result, IC chips and other electronic components are frequently exposed to electrostatic hazards throughout production, testing, storage, and transportation.

Effects of ESD on Electronic Components

Electrostatic discharge can release extremely high voltage and current within a very short time, causing various forms of damage to electronic devices, particularly IC chips.

Physical Damage

High-voltage ESD events can break down gate oxides, PN junctions, or metal interconnects inside an IC chip, leading to melting, burning, or permanent dielectric breakdown. This type of damage is irreversible and represents one of the most severe forms of ESD impact on IC chips.

Performance Degradation

Even when ESD does not cause immediate physical failure, it can still degrade device performance. For example, memory ICs may experience data loss, analog IC chips may exhibit parameter drift, and sensor ICs may suffer reduced sensitivity. These issues demonstrate how electrostatic discharge damages integrated circuits in subtle but dangerous ways.

Reduced Reliability

Repeated or latent ESD damage can significantly reduce the long-term reliability of electronic components. In applications requiring high stability—such as industrial automation, medical electronics, and aerospace systems—ESD-induced failures in IC chips can result in serious operational risks.

Typical ESD Impact Scenarios in Real Applications

- IC chip damage in SMT assembly lines: During high-speed SMT placement, inspection, or manual handling, insufficient grounding or inadequate ESD control can easily expose IC chips to electrostatic discharge.

- ESD failures caused by improper packaging during storage and transportation: Without anti-static packaging, IC chips and electronic components may accumulate charge due to friction and environmental conditions, leading to hidden ESD damage before reaching end users.

- Potential ESD-related failures in industrial control and medical devices: In mission-critical systems, ESD-induced latent defects in IC chips can cause intermittent malfunctions, compromising safety and system reliability.

Damage Mechanisms of Electrostatic Discharge

Thermal Effects

The rapid energy release during an ESD event can generate intense localized heat, damaging semiconductor materials and internal structures within IC chips.

Electrical Effects

The transient high current produced by ESD may exceed the electrical tolerance of an integrated circuit, causing dielectric breakdown or junction failure.

Mechanical Effects

Strong electric fields generated by electrostatic discharge can induce mechanical stress inside IC chips, potentially leading to micro-cracks or broken interconnects.

Common ESD Failure Modes in IC Chips

Electrostatic discharge can damage IC chips in multiple ways, depending on discharge energy, device structure, and fabrication technology. Understanding common ESD failure modes is essential for diagnosing field failures and implementing effective ESD protection for integrated circuits.

Gate Oxide Breakdown

Gate oxide breakdown is one of the most common and critical ESD failure mechanisms in modern IC chips, particularly in CMOS devices. Due to the extremely thin oxide layers used in advanced semiconductor processes, even a short ESD pulse can exceed the dielectric strength of the gate oxide.

Once a breakdown occurs, the affected IC chip may experience increased leakage current, functional instability, or complete device failure. In many cases, gate oxide damage results in latent ESD defects that only manifest after extended operation.

Junction Burnout

Junction burnout occurs when the high current generated during an ESD event passes through PN junctions within an IC chip. The resulting localized heating can permanently damage junction regions, leading to abnormal electrical behavior or total functional loss.

This failure mode is more frequently observed in power IC chips and analog integrated circuits, where higher current densities are present.

Metal Interconnect Melting

During a high-energy electrostatic discharge, excessive current may flow through the metal interconnects inside an integrated circuit. If the current exceeds the thermal limits of the metal lines, localized melting or open-circuit failure can occur.

Metal interconnect damage often leads to immediate and catastrophic IC chip failure, making it one of the most destructive ESD-related failure mechanisms.

Latent ESD Damage

Latent ESD damage refers to hidden defects caused by electrostatic discharge that do not result in immediate failure. Instead, the IC chip continues to function but with weakened internal structures.

Over time, thermal stress, electrical cycling, or environmental factors can cause these latent defects to evolve into functional failures. Latent ESD damage is particularly dangerous because it significantly reduces IC chip reliability while remaining undetected during standard electrical testing.

Prevention and Protection Measures

To mitigate the risks associated with ESD, manufacturers and engineers implement systematic electronic component ESD protection methods, especially for IC chips.

ESD Control Programs

Establishing and strictly following ESD control procedures—including the use of anti-static clothing, wrist straps, grounded workstations, and ESD-safe packaging—is essential for protecting IC chips.

Grounding and Shielding

Proper grounding of equipment, tools, and personnel helps eliminate static charge buildup. Shielding materials can further reduce ESD exposure to sensitive IC components.

Humidity Control

Maintaining environmental humidity between 40% and 60% effectively reduces static electricity generation, lowering the ESD risk for IC chips.

ESD Protection Devices

In circuit design, incorporating ESD protection components such as TVS diodes and metal oxide varistors (MOVs) helps absorb transient energy and safeguard IC chips and integrated circuits from electrostatic damage.

In the electronics manufacturing industry, standards such as IEC 61340 and ANSI/ESD S20.20 clearly define requirements for electrostatic discharge protection, providing authoritative guidance for effective ESD management.

Conclusion

The impact of electrostatic discharge on sensitive electronic components is multifaceted, ranging from immediate physical damage to long-term performance degradation and reliability reduction. As IC chip geometries continue to shrink and integration levels increase, ESD risks become more pronounced.

By implementing comprehensive ESD protection strategies and adhering to recognized industry standards, manufacturers can significantly reduce ESD-related failures, enhance IC chip reliability, and extend the service life of electronic products.