Understanding PCBA: The Heart of Electronic Devices

In the world of electronics, PCB and PCBA are terms that often come up in discussions related to circuitry and device manufacturing. While PCB (Printed Circuit Board) serves as the foundation, PCBA (Printed Circuit Board Assembly) takes the concept to the next level. In this article, we’ll delve into the intricacies of PCBA, exploring its significance, components, and how it plays a crucial role in bringing electronic devices to life.

What is PCBA?

PCBA, or Printed Circuit Board Assembly, refers to the process of populating a bare PCB with electronic components like resistors, capacitors, integrated circuits, and more. The bare PCB acts as a platform, providing a substrate for these components and the interconnections necessary for the circuit to function. PCBA is a critical step in the manufacturing of electronic devices, transforming a passive PCB into a functional and intelligent piece of technology.

The PCBA Process: The PCBA process involves several key steps:

- Component Placement: This step involves precisely positioning electronic components onto the bare PCB. Advanced machinery is often used to ensure accuracy and efficiency.

- Soldering: Once components are in place, soldering is employed to create permanent connections between the components and the PCB. Soldering can be done using wave soldering or reflow soldering, depending on the specific requirements of the assembly.

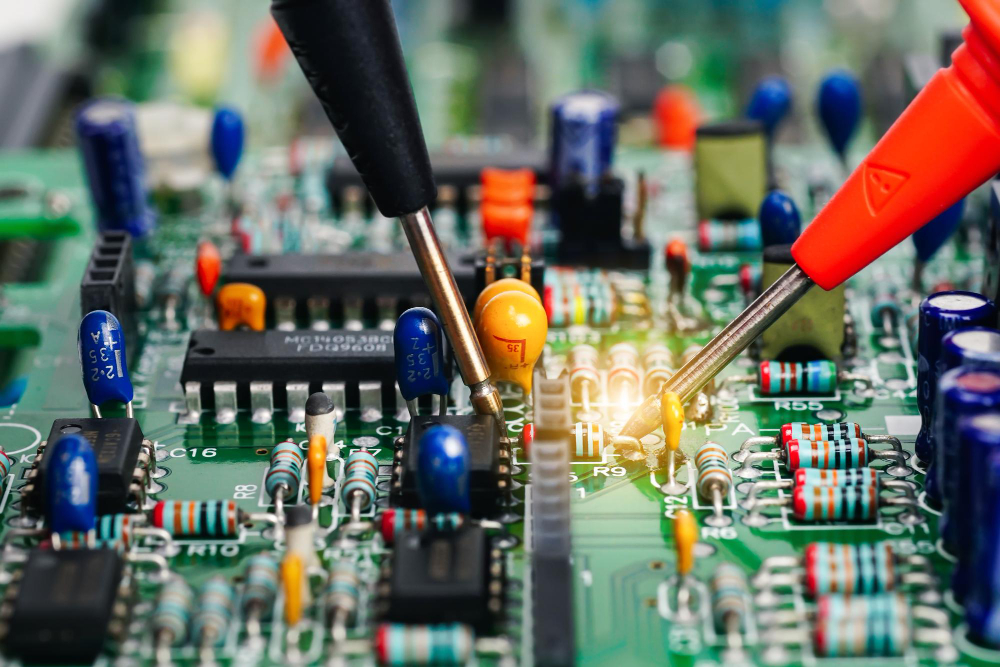

- Inspection: Quality control is a crucial aspect of PCBA. Automated and manual inspections are carried out to detect any defects, ensuring the reliability and functionality of the assembled PCB.

- Testing: To guarantee the functionality of the electronic device, comprehensive testing is performed. This may include functional testing, in-circuit testing, and other methods to verify that the assembled PCB meets the required specifications.

Components of PCBA:

PCBA incorporates various electronic components, each playing a specific role in the overall functionality of the device. Some common components include:

- Resistors: Control the flow of electric current.

- Capacitors: Store and release electrical energy.

- Integrated Circuits (ICs): Perform specific functions within the circuit.

- Connectors: Facilitate external connections.

- Diodes: Control the direction of electric current.

- Inductors: Store energy in a magnetic field.

The Significance of PCBA:

PCBA is a crucial stage in the manufacturing process of electronic devices. It transforms a static PCB into a dynamic and functional entity. The precision and reliability of PCBA directly impact the performance and longevity of electronic devices. From consumer electronics like smartphones and laptops to complex industrial machinery, PCBA is the backbone that enables these devices to carry out their intended functions.

PCBA vs. PCB:

While PCB and PCBA are closely related, it’s essential to distinguish between the two. A PCB is a physical board with copper traces that form the electrical connections. PCBA, on the other hand, includes the populated PCB with all the electronic components, turning it into a complete and functional circuit.

Understanding Printed Circuit Boards (PCBs):

A Printed Circuit Board is the fundamental building block of electronic devices. This board serves as a substrate, typically composed of non-conductive materials such as fiberglass or epoxy. The surface of the PCB is etched with conductive pathways, often made of copper, that form a circuit according to the device’s specifications. These conductive traces facilitate the flow of electrical signals between various components, creating a cohesive electronic system.

The PCB design is a critical phase, involving the layout of components, placement of vias, and determination of trace widths. Modern PCBs can be single-layered or multi-layered, depending on the complexity of the electronic system they are meant to support.

Printed Circuit Board Assembly (PCBA):

Once the bare PCB is fabricated, the next step is the assembly of electronic components. This intricate process is known as Printed Circuit Board Assembly (PCBA). PCBA involves populating the PCB with a myriad of components, ranging from resistors and capacitors to integrated circuits and other active or passive devices.

The assembly process is meticulously executed, often with the aid of automated machinery. Components are precisely placed on the designated spots on the PCB, and the connections are established through soldering. Surface Mount Technology (SMT) and Through-Hole Technology (THT) are two common techniques employed in PCBA, each with its own advantages and use cases.

SMT vs. THT:

Surface Mount Technology involves attaching components directly onto the surface of the PCB, eliminating the need for holes. This method is efficient, compact, and suitable for high-density circuitry. In contrast, Through-Hole Technology involves inserting component leads through holes in the PCB and soldering them on the opposite side. THT is often preferred for components requiring robust mechanical support.

Final Integration:

Once the components are securely attached, the assembly undergoes inspection to ensure the absence of defects such as soldering bridges or misplaced components. Advanced testing methods, including Automated Optical Inspection (AOI) and In-Circuit Testing (ICT), validate the functionality and integrity of the assembled PCB.

Conclusion:

In the ever-evolving world of electronics, understanding the significance of PCBA is crucial. It’s the final step that breathes life into a bare PCB, turning it into a fully functional electronic device. As technology advances, the importance of precise and efficient PCBA processes becomes increasingly evident in delivering reliable and innovative products to consumers.

To explore more about the difference between PCB and PCBA, visit PCBA.