PCB Milling: Tips You Need to Know

- 1 What is PCB milling?

- 2 Why PCB milling is preferred over other PCB manufacturing processes

- 2.1 PCB milling is the best method to create circuit boards with tight tolerances

- 2.2 Milling can be used to create PCBs with thin features

- 2.3 Milling is the best method for creating PCBs with gaunt features

- 2.4 The process can be used when making intricate shapes

- 3 Bottom-line

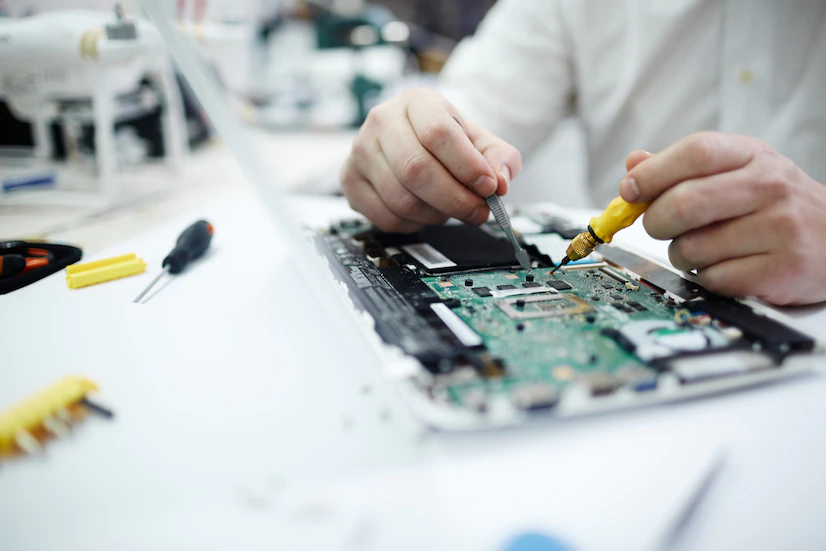

Printed circuit boards (PCBs) are a vital element of any modern electronic gadget. To make quality products, a series of processes are used in PCB manufacturing. One recommended method is CNC milling, which involves removing copper tracts from the PCB sheet.

In this post, you will learn all about PCB milling and the vital tips you need to know about milling.

What is PCB milling?

PCB milling is a process of removing materials from a workpiece. PCB milling, also known as isolation milling, is a manufacturing process where no chemicals are used. Also, it has become a popular PCB manufacturing process due to its numerous benefits.

Both PCB milling and etching aim to achieve the same results. However, milling has become the ideal process because it is chemical-free. This means it is ideal for use in a home or office since there is no exposure to hazardous chemicals.

Hence, even though both etching and milling are subtractive processes, milling does not rely on chemicals. However, even though milling is an excellent process for most people, the quality of the circuit boards depends on various factors.

Many factors affect the quality of the board during the process. Some of them include milling accuracy and control, the trueness of the system, and other factors.

PCB milling comes with numerous benefits over other procedures. First, it is possible to create complex designs with milling. Also, there is the flexibility of making changes to your design.

Besides, you do not fabricate your circuit board with hazardous chemicals since there are no chemicals. In addition, there are no issues with disposing of the chemicals once you are done.

PCB milling process:

The PCB milling process involves two systems: software and hardware. The software system has two types: vector and raster software. Milling machine manufacturers supply both.

The hardware system is the numerically controlled machine. It has either a port or serial to connect to the central controller. All you need is to know how to operate, and you are good to go. The process is easy, faster, and very accurate.

Tips you need to know about the PCB milling process

- PCB milling is a vital process for removing redundant copper from the board. It helps to create paths and signal traces based on the design.

- In many cases, the milling process takes 30 minutes. Nevertheless, some factors can affect the duration of the process. For instance, the circuit board’s dimension, the bit’s thickness, and other elements can affect the duration.

- The milling process can be done in a lab environment with harmful chemicals.

- The PCB machine maker can provide you with PCB milling technology.

- If you have never used a milling machine before, it is essential to practice before you start producing.

- With PCB milling, producing thin and minimal features and even working on complicated PCB designs is possible.

Why PCB milling is preferred over other PCB manufacturing processes

PCB milling is the best method to create circuit boards with tight tolerances

Milling is one of the best ways to develop tight-tolerance circuit boards. This is because it uses a rotating cutting tool to eliminate excess materials.

In addition, it can be used to make PCBs of a wide variety of sizes and shapes. So, if you are looking for a method to create printed circuit boards with tight tolerances, milling is the best option.

Milling can be used to create PCBs with thin features

Another great thing about milling is that it can be used to create circuit boards with fine features. This process allows manufacturers to make more minor features than those made through other methods.

Hence, PCB milling is beneficial when creating boards with a high density of features. Whether there are many features, the method is a great choice.

Milling is the best method for creating PCBs with gaunt features

PCB milling is a process that you can use to develop PCBs with thin features. It is a procedure that involves using a machine to remove materials from the PCB to create any desired feature.

Milling is the best option for making PCBs with thin features because you can quickly tell the amount of material you want to remove. Hence, it is possible to create features with a high degree of accuracy. Moreover, milling is a speedy process, enabling a large number of PCBs to be produced within a short period.

Hence, milling is considered by many people when making thin features because it is fast and accurate compared to other methods.

The process can be used when making intricate shapes

PCB milling is the best manufacturing process for people with complicated designs. This process allows very complex shapes to be cut into the material. In addition, it can be used to create features that might be difficult to make using other manufacturing methods.

Milling is a process that you can use to create small and precise features. Hence, making circuit boards with complicated shapes and designs is possible. You can also use the process to make vias and small holes in the circuit board.

Milling is one of the fastest PCB manufacturing processes. Hence, it is possible to get many PCBs easily and quickly. Moreover, it is a very accurate process essential when creating high-quality PCBs.

Bottom-line

Today, PCB milling is an economical way of creating high-quality printed circuit boards. Although there are some drawbacks, such as the high cost of the milling machine, it is the best PCB manufacturing process for creating better and more robust boards.

Milling is generally a good option for creating PCBs. Whether you want to create boards with thin features, fine-pitch features, or tight tolerances, milling is the best alternative. The above milling tips will help you get started.