Advantages Of Eye-Flex Conveyor Belting

- 1 Industries That Use Eye-Flex Conveyor Belts

- 1.1 Food Processing Industry:

- 1.2 Automobile Industry:

- 1.3 Packing Industry:

- 1.4 Chemical Industry:

- 1.5 Pharmaceutical Industry:

- 1.6 Textile Industry:

- 1.7 General Industrial:

- 2 Conclusion:

- 2.1 FAQs:

- 2.1.1 Are Eye-Flex conveyor belts suitable for hygienic environments in the food industry?

- 2.1.2 What advantages do Eye-Flex conveyor belts offer in terms of maintenance?

- 2.1.3 Can Eye-Flex conveyor belts handle heavy loads in industrial settings?

- 2.1.4 Are Eye-Flex conveyor belts resistant to corrosion?

- 2.1.5 Are Eye-Flex conveyor belts customizable for specific applications?

- 2.1.6 How do Eye-Flex conveyor belts contribute to product safety in the food industry?

- 2.1.7 Do Eye-Flex conveyor belts offer cost savings over time?

In Short:

- Robust Design: Eye-Flex conveyor belts feature a modular design with reinforcing plates and steel cross rods, offering a durable and long-lasting solution for various industries.

- Versatile Applications: The adjustable wire belt surface and modular design make Eye-Flex suitable for many applications, including high-load scenarios in hygienic environments and processes prone to product toppling.

- Low Maintenance: As a positively driven belt, Eye-Flex eliminates the need for precise tracking and tightening, reducing maintenance requirements compared to friction-driven alternatives.

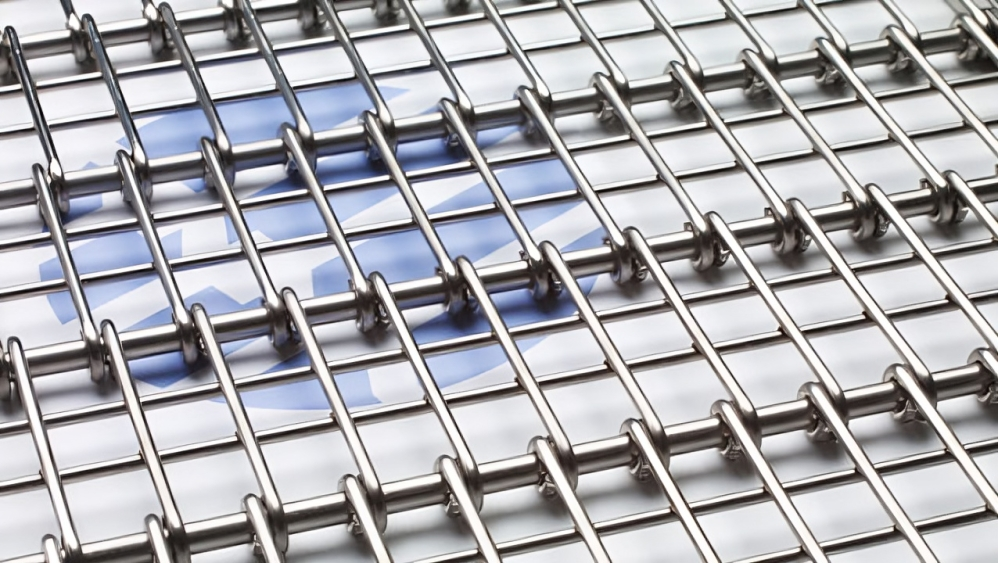

The Eye-Flex conveyor belting is ideal if your company requires a robust, long-lasting belt. Conveyor Belt manufacturers have reinforcing plates and steel cross rods for Eye-Flex’s modular design. These support a highly customizable array of wire connections that give Eye-Flex its product-carrying surface and add to the belt’s high draw strength.

The Eye-Flex belt’s modular design and adjustable wire belt surface provide endless application possibilities. The carrying surface arrangement can be specified without regard to the load requirements.

High-load applications in hygienic settings are one use case where it excels. Because of its open construction, hygiene personnel have less work because clean-in-place washdown processes are simple.

Moreover, the panel design of Eye-Flex offers a level and sturdy carrying surface. This also makes it appropriate for processes with a chance of product toppling, including pasteurization and canning.

Lastly, compared to friction-driven alternatives, Eye-Flex is a positively driven belt, which means that maintenance crews do not need to track and tighten the belt system precisely.

Industries That Use Eye-Flex Conveyor Belts

Eye-Flex is a very adaptable material with several uses in various sectors. Typical uses for them include:

Food Processing Industry:

Eye-Flex conveyor belts are extensively utilized in food processing plants for operations like baking, cooking, cooling, freezing, drying, and washing. Because of its open design, Eye-Flex is appropriate for applications where cleanliness and hygiene are critical since it facilitates adequate drainage and airflow.

Because of their advantages and distinctive appearance, eye-flex conveyor belts are extensively used in food processing. These belts have a flexible and robust conveyor surface because they are constructed of interlocking metal segments joined by cross rods. Materials like stainless steel, which are corrosion-resistant and easy to clean, are used to make Eye-Flex belts. This makes them perfect for food processing, where hygienic conditions are vital. Because of the open mesh design of Eye-Flex belts, there is good drainage and airflow, which helps keep moisture and debris from building up. This ensures food safety compliance by lowering the possibility of bacterial development and product contamination.

Because Eye-Flex belts are temperature-tolerant, they can be used for various tasks.

Automobile Industry:

Painting, coating, drying, and assembly are among the activities in automobile production facilities where Eye-Flex belts are utilized. Eye-Flex can transport heavy automotive parts through several production phases due to its strength and endurance. These belts can handle a large variety of items. Additionally, they work well with conveyor systems that are curved or straight.

The interlocking metal segments provide the belts with high tensile strength and longevity, ensuring performance even under demanding operating conditions and large loads.

Packing Industry:

Sorting, conveying, and packing products are just a few of the jobs that Eye-Flex conveyor belts are used for in packaging factories. Because of its adaptability to various product shapes and sizes, Eye-Flex is perfect for a broad range of packaging applications. Eye-Flex belts can be tailored to match the width, length, and pitch needed for a particular application. This enables the optimal integration of existing conveyor systems and guarantees effective product handling.

Eye-Flex conveyor belts are comparatively more straightforward to maintain than standard conveyor belts with intricate features. They are more productive and need less downtime since they contain fewer parts and can be readily dismantled for maintenance or cleaning. Although eye-flex conveyor belts may initially cost more than typical conveyor systems, they can save costs over time due to their long-term durability, low maintenance needs, and decreased chance of product contamination.

Chemical Industry:

Eye-Flex belts are used for transporting, mixing, blending, and drying chemical compounds in chemical processing plants. Because of its corrosion resistance, Eye-Flex can be used in harsh conditions and with corrosive chemicals.

Pharmaceutical Industry:

Pharmaceutical production facilities employ Eye-Flex conveyor belts for coating, drying, sterilizing, and packing pharmaceutical items. Eye-Flex is perfect for pharmaceutical applications because of its smooth surface, which makes cleaning easier and reduces product contamination.

Textile Industry:

Eye-Flex belts are used for moving, drying, curing, and dying textile materials in manufacturing facilities. Because of its open form, which facilitates effective heat transfer and airflow, Eye-Flex is a good choice for textile processing applications.

General Industrial:

Eye-Flex conveyor belts are used in several sectors for material handling, recycling, metalworking, and woodworking, among other industrial operations. Eye-Flex’s adaptability, robustness, and customizable design can benefit many industrial applications.

Conclusion:

Eye-Flex conveyor belts present a robust and versatile solution for numerous industries, including food processing, automotive, packaging, chemical, pharmaceutical, textile, and general industrial applications. With its durable design, adaptability, and low maintenance needs, Eye-Flex offers efficiency and reliability in material handling operations.

FAQs:

Are Eye-Flex conveyor belts suitable for hygienic environments in the food industry?

Yes, Eye-Flex belts are ideal for the food industry due to their open design facilitating easy cleaning, drainage, and airflow, thus ensuring compliance with hygiene standards.

What advantages do Eye-Flex conveyor belts offer in terms of maintenance?

Eye-Flex belts require less maintenance compared to traditional conveyor belts because of their positively driven system, eliminating the need for precise tracking and tightening.

Can Eye-Flex conveyor belts handle heavy loads in industrial settings?

Yes, Eye-Flex belts are designed to withstand high loads and demanding operating conditions due to their robust construction with reinforcing plates and steel cross rods.

Are Eye-Flex conveyor belts resistant to corrosion?

Yes, Eye-Flex belts are made from materials like stainless steel, offering corrosion resistance, making them suitable for use in chemical processing plants and other corrosive environments.

Are Eye-Flex conveyor belts customizable for specific applications?

Yes, Eye-Flex belts feature a modular design that allows for customization of the carrying surface arrangement to meet the requirements of different applications.

How do Eye-Flex conveyor belts contribute to product safety in the food industry?

Eye-Flex belts help ensure product safety by minimizing the risk of bacterial development and product contamination through effective drainage, airflow, and easy cleaning.

Do Eye-Flex conveyor belts offer cost savings over time?

Yes, despite potentially higher initial costs, Eye-Flex belts can save costs over time due to their long-term durability, low maintenance needs, and reduced risk of product contamination, leading to increased productivity and efficiency.