DPF Options for Car Builders and Repairers

For engine manufacturers to comply with U.S. Environmental Protection Agency (EPA) emissions guidelines, diesel particulate filters (DPFs) were introduced to diesel engines used on public roads in 2007.

Before this, emission restrictions were 2g/bhp-hr (grams per brake horsepower-hour) for NOx emissions and 0.1g/bhp-hr (particulate matter) emissions.

A new restriction of 0.01g/bhp-hr for PM emissions became fully applicable for vehicles made in the 2007 model year, while a new limit of 0.2g/bhp-hr for NOx emissions was phased between 2007 and 2010. These limitations continue to be the current standards for diesel engine emissions.

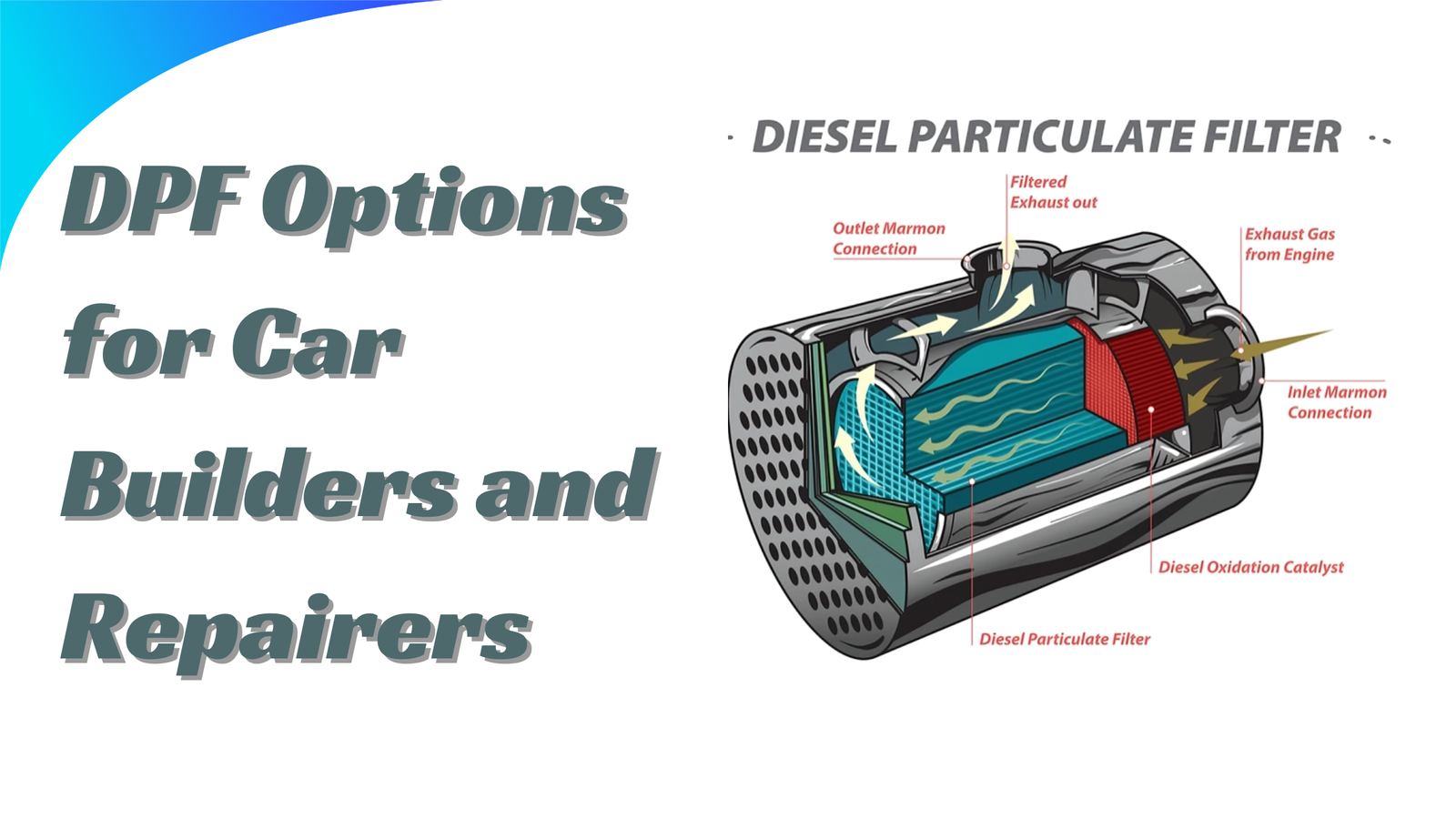

The DPF has thousands of micropores to collect particulate matter and ash from the engine.

Particulate matter and ash from the engine fill the DPF as it gathers them, causing a backpressure inside the filter.

A regeneration to oxidation is performed once the backpressure reaches a certain threshold. Oxidation occurs when particulate matter is broken down into gases and non-combustible substances.

The car owner must clean the filter regularly since the non-combustible material and ash from oil consumption cannot be eliminated.

Sometimes, they must replace the entire filter, especially if it’s too dirty or worn out.

As vehicles equipped with early Diesel Particulate Filters (DPF) become older, a car repairer must know how to repair these vehicles.

Always start with the diagnosis

Finding soot in the exhaust is one way to determine the DPF’s health. Soot indicates that the DPF’s core is broken and no longer functions as a filter.

Additional scan tool diagnosis is crucial, and removal for a physical examination is strongly advised.

If the ceramic core is removed, look for evidence of melting, crumbling, or cracking on the rear side of the core using a bore scope.

Additionally, check the DPF core’s back surface for any stains. Both black and white staining are signs of internal damage brought on by high temperatures, the use of the wrong crankcase oil, or an incompatible fuel additive.

The DPF’s core can remain if the ceramic’s back is light grey or immaculate white. Before you replace or fix the DPF, you must address the root cause of the failure.

Some of the common causes of failure include:

- Regular urban drive cycles without driving for extended periods

- Engine operating at extremely low temperatures

- Inappropriate or tainted lubricant—the right “low solids” DPF oil is required.

- Tainted or improper fuel: biodiesel, fuel additives

- Air leaks in the induction and intercooler systems.

- Broken or blocked hoses and pipes for pressure sensors

- Inaccurate DPF temperature, pressure, or differential pressure switch/sensors

- Glow plugs

- Misleading Mass Air Sensor

- The corrosion

- Fractures in the internal DPF filter

- A defective, broken, low-quality, or subpar high-flow catalytic converter

- EGR valve malfunctioning or getting jammed

- Leaking turbo oil seals and turbo failure

- Leaking, jammed, or incorrectly calibrated injectors.

Clean the DPF if only blocked

Some people rush to replace the DPF filters, but you shouldn’t.

Aerosol DPF cleaning for cars may be effective for minor soot blockages, but it cannot repair structural damage or clear a DPF that is wholly clogged with ash.

Particulate matter cannot pass through the ceramic core of a DPF. In such a case, you have to replace the unit.

If there is no damage to the DPF core, you only need to clean it.

Gloves and dust masks are necessary personal protective equipment when cleaning. After placing the filter inside the cleaning machine, it is safe since the ash and PM are drawn into a two-stage dust collection system with a HEPA filter.

Minute particles are intended to be present in HEPA filters.

Proper disposal of the ash and PM from the cleaned DPF is necessary. Ensure that you adhere to all applicable local, state, and federal regulations for handling and disposal procedures.

When reinstalling the filters, remember to use weld bungs. These bungs provide a better fitting that stops leaks in the exhaust system.

You should note that engine performance could be lowered, and fuel consumption from the gas tanks could rise due to unfinished or unstable housing.

There’s also a chance that dangerous diesel fumes will be emitted, so ensure you get the right bungs from DPF Parts Direct or any other reputable store.

Replace the DPF if the internal structure is damaged

It is not an option to remove or modify the DPF because doing so is against the law in every jurisdiction.

While a genuine original equipment manufacturer (OE) replacement DPF is undoubtedly worthwhile, the cost can be high.

The condition of used DPFs is unclear, so you must research and find a quality one that will fit the car you are building.

As you replace the DPF, you should note that you can’t reset the car’s ECU during the installation; it can only be reset to start at “0” for a fresh DPF installation.

You also can’t adjust it to fit a secondhand, partially-filled DPF that has been in use. You should note that doing so can result in persistent error codes and problems. And you don’t want this.

An aftermarket DPF can be another affordable option; it will perform like the original equipment specifications for temperature resistance, holding capacity, and flow rates afterward.

These aftermarket units are an easy and quick swap out for the original DPF and typically come with fresh gaskets, washers, nuts, and other parts.

Parting shot

As a car repairer or builder, you have two options with DPF. You are replacing or cleaning them. As we have seen, you should clean them if they have no significant damage to them. When reinstalling the filters, ensure they are in place and don’t move around.

You don’t need to clean the filters if they are too damaged or worn out. Instead, replace them, and as we have seen, there are plenty of options you can go with. It’s up to you to choose the most sensible choice for the car and your client.