What you need to know while outsourcing a box build assembly?

Using third-party vendors means that another company provides all or part of the goods or services you need or need to deliver to your customers. Outsourcing specific tasks to an external partner are often used in the event of increased activity or complexity of a given process. It is no different in the case of outsourcing a box build assembly. However, the question arises: how to order the cooperation to be successful?

At first glance, it may seem that outsourcing box build assembly is a straightforward process. It is enough to find a subcontractor providing this type of service, send him the necessary files and a list of materials, and that’s it. Then, the assembly process could start moving. In practice, however, it very often turns out that numerous practical problems arise when establishing cooperation with a supplier.

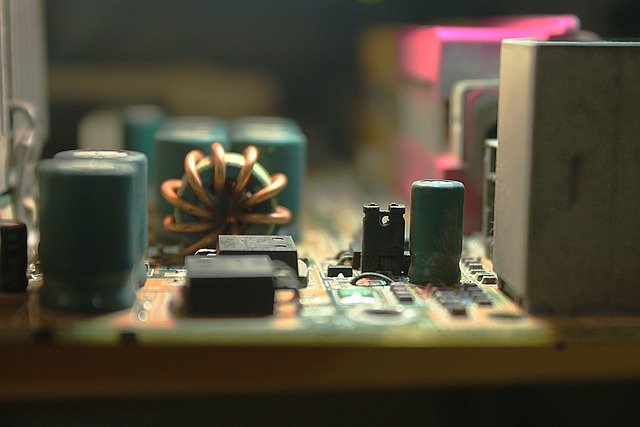

The wording “box build” can mean many different things. It can be a PCBA board in a small housing or a large cabinet filled with many wires. Box build can also stand for a fully integrated electromechanical system with electronics and pneumatics.

That being said, you may be wondering how to outsource your electronics production to get a fair quote and then be satisfied with the entire process and collaboration. So, let us introduce you to this topic.

What do you need to know while outsourcing a box build assembly?

First of all – experience

When outsourcing, you entrust all or a significant part of the box-build assembly process to a specialized external service provider, and you probably want to believe in their professionalism. Indeed, it is imperative that the electronics manufacturing services (EMS) partner has the appropriate level of knowledge and, above all, experience when it comes to collaboration efficiency. Thanks to many years of experience, your partner will be flexible and reliable, thanks to which you will be able to focus on other essential aspects of your business.

Partnering up with an experienced EMS can also turn out to be significant cost savings for your organization. A box build assembly supplier, who has been operating on the market for many years, can offer you suitable solutions in improving production processes and even suggest some design improvements that may reduce production costs and time to market. We hope that we have convinced you of the importance of the experience of your potential EMS partner and why this issue should be important to you. So let’s check how you should outsource box build assembly.

Handing over the materials

Bill of materials (BOM) is probably the first thing your chosen EMS supplier asks you about. This list should include all the main components, as well as an indication of whether you intend to define such elements as screws, nuts, adhesives, heat shrink sleeves or wires and their identifiers yourself, or whether you entrust their selection to an external partner. Taking care of these elements is sometimes underestimated, yet they constitute an actual cost that must be defined so that their sudden appearance does not negatively impact production.

You can also specify the scope of “free issued” in the BOM, that is, the material you will deliver. At the same time, the bill of materials should clearly state which materials should be purchased by EMS. However, it is good practice to outsource EMS purchase of all necessary materials. Why? The entrusted material must undergo the same verification processes (e.g., entry inspection) as the purchased by the supplier, unnecessarily exposing you to additional costs. Professional EMS deals with the entire supply chain, including purchasing materials.

Box build assembly

After the BOM, the EMS supplier will ask you to provide ready-made CAD files that he can rely on during the assembly process. 3D CAD models help EMS visualize how you should present the final product. Therefore, it is vital that you also include a layout drawing showing the layout of the main components and their locations, including, for example, cable routing, to your model.

Again, we will refer to the EMS experience because the company you outsource to box build assembly should have appropriate expertise in 3D CAD model design to provide advice and assistance to update the projects. A competent EMS should also assemble cable harnesses and assembly control cabinets. These are the stages of electronics production, requiring very professional knowledge and previous experience.

When deciding to work with a given EMS, also pay attention to whether it offers box build assembly to systems integration services. In other words, the question is whether the contractor will make cable harnesses assembly and cabinet assembly for you. These are services that require a lot of knowledge; therefore, not every EMS will perform them. It is worth discussing this issue with a potential contractor before establishing cooperation.

Here you can find more information about Box Build and Electro-Mechanical Assembly: https://asselems.com/en/box-build-electro-mechanical-assembly

Test opportunities

The last but not less critical issue you should consider when starting cooperation with EMS is testing. In the case of box build assembly, as with any other electrical system, you should indicate at least the basic safety tests to be performed. A good EMS should tell you what type of tests should be conducted for a given product in case of your doubt.

One of the more important tests to consider is the functional test (FCT). It is a test performed at the final production stage, during which the correct operation of all installed elements is verified. Testing devices simulate the target operating conditions of the device, thanks to which it is possible to demonstrate how the device will work in natural conditions. These tests are carried out using measurement systems or testers dedicated to a given device, provided by the customer or created by EMS.

Comprehensive box build assembly thanks to outsourcing

Outsourcing box build assembly is not only a way to significantly reduce investment expenses. First of all, cooperation with a good contractor guarantees professional supply chain management, the ability to produce regardless of the desired volume, and the comprehensive support of a team of specialists. Achieving high production competencies by the contract electronics supplier results from many overlapping factors, thanks to which order the assembly of such an EMS allows you to minimize the risk of errors and let you focus on the development of your business.

Successful cooperation with a contractor results from the passage of time and mutual trust, which you cannot build right away. Certainly, however, taking care of the above-described elements when establishing cooperation makes both you and your contractor sure that you understand each other’s expectations.