Ultimate Guide to Laser Cutting and Laser Cutting Machine

- 1 History of Laser Cutting

- 2 Types of Lasers Used in Cutting

- 2.1 CO2 Lasers:

- 2.2 Fiber Lasers:

- 2.3 Nd: YAG and Nd:

- 2.4 Diode Lasers:

- 3 How Laser Cutting Works

- 3.1 Generation of the Laser Beam:

- 3.2 Amplification of the Beam:

- 3.3 Directing the Laser:

- 3.4 Focusing the Laser:

- 3.5 Cutting the Material:

- 3.6 Moving the Material or Laser:

- 3.7 Cooling System:

- 4 Advantages of Laser Cutting

- 5 Choosing the Right Laser Cutting Machine

- 5.1 Purpose and Material:

- 5.2 Work Area Size:

- 5.3 Laser Power:

- 5.4 Software Compatibility:

- 5.5 Cooling System:

- 5.6 Safety Features:

- 5.7 Budget:

- 5.8 Ease of Maintenance:

- 5.9 Vendor Reputation:

- 5.10 Expandability and Upgrades:

- 5.11 Training and Support:

- 6 Future of Laser Cutting

- 6.1 Greater Precision with AI:

- 6.2 Increased Automation:

- 6.3 Eco-friendly Advancements:

- 6.4 Faster Machines:

- 6.5 Adaptation to New Materials:

- 6.6 Integration with the Internet of Things (IoT):

- 6.7 Advanced Software Integration:

- 6.8 3D Laser Cutting:

- 6.9 Personal Desktop Laser Cutters:

- 6.10 Enhanced Safety Features:

- 7 Conclusion

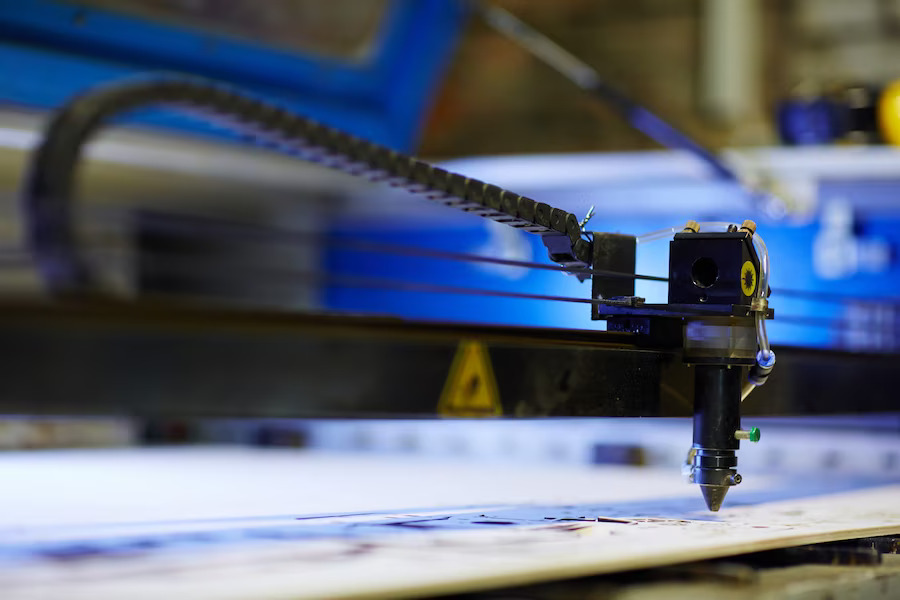

Laser cutting, an advanced technological marvel, has drastically shifted the paradigms of the manufacturing and design world. Laser cutting allows for impeccably precise designs by leveraging intense beams of light. This comprehensive guide offers detailed insights into the fascinating universe of laser cutting, its transformative history, multifaceted benefits, and the intricacies of the machinery that powers it.

History of Laser Cutting

The odyssey of laser cutting began in the throes of the 20th century, a period marked by rapid technological advancements. Theodore Maiman’s invention of the ruby laser in 1960 sowed the seeds for what would soon revolutionize the manufacturing landscape. By harnessing the powerful precision of light, industries swiftly identified lasers as the future of detailed crafting. Over the decades, this technique has evolved, witnessing transformations in its applications, efficiency, and accessibility. Today, as we stand on the cutting edge of this innovation, it’s awe-inspiring to trace its journey from a laboratory concept to a mainstay in modern fabrication.

Types of Lasers Used in Cutting

With its precision and efficiency, laser cutting leans heavily on the laser employed. These lasers are meticulously designed, with each type catering to specific materials and thicknesses.

Here’s a deeper dive into the main lasers used in the industry:

CO2 Lasers:

Originating from a gas mixture dominated by carbon dioxide, these lasers are ideal for cutting, boring, and engraving. Often used with materials like wood, acrylic, paper, and some metals, CO2 lasers have proven versatile with many applications.

Fiber Lasers:

These solid-state lasers are gaining traction for their efficiency and speed, especially in metals. Using an optical fiber infused with rare-earth elements, fiber lasers deliver a high-powered beam, making them excellent for tasks demanding precision.

Nd: YAG and Nd:

YVO Lasers: Neodymium-doped crystals power these lasers primarily geared for engraving and welding. They can process ceramics, metals, and plastics and offer a harmonized balance of intensity and finesse.

Diode Lasers:

Comprising multiple diodes, these lasers are generally used for engraving rather than cutting. They work best with plastics, leather, and some thin metals.

Understanding the nature of these lasers allows users to select the most suitable one for their specific project, ensuring efficiency and achieving the desired outcome. As technology progresses, we’ll likely see further advancements and specializations within these categories.

How Laser Cutting Works

Laser cutting is a process that may seem complex, but when broken down, it’s a fascinating combination of physics, precision, and technology.

Let’s delve into the basic mechanics and principles behind this advanced technique:

Generation of the Laser Beam:

At the heart of the process is the laser resonator. Here, energy is introduced to the laser medium, triggering a physical phenomenon known as stimulated emission. This produces a highly concentrated beam of light—what we commonly refer to as the “laser.”

Amplification of the Beam:

The generated light bounces back and forth between mirrors in the resonator. This repetitive reflection amplifies the light, making it more potent.

Directing the Laser:

Once sufficiently amplified, the laser beam exits the resonator. It travels through the machine’s beam path, where various optical methods, like lenses or curved mirrors, help refine and direct the laser beam precisely onto the material.

Focusing the Laser:

The beam, although powerful, is then narrowed down to an incredibly fine point using a lens. This focused beam has a diameter as tiny as a tenth of a millimeter, ensuring precision in the cutting process.

Cutting the Material:

As the focused laser beam hits the material, it rapidly heats, melts, or vaporizes it at the point of contact. In some setups, a gas jet—like nitrogen or carbon dioxide—blows away the molten material, ensuring a clean cut.

Moving the Material or Laser:

Depending on the machine’s design, the material will move under a stationary laser, or the laser will move over a fixed material. This movement is guided by computer-aided design (CAD) files, ensuring the cut aligns perfectly with the desired design.

Cooling System:

A cooling system is typically integrated due to the intense heat generated during the process. This system prevents the laser source from overheating, ensuring consistent performance and prolonging the machine’s lifespan.

Laser cutting transforms digital designs into physical objects with unmatched precision. Combining computer technology with high-energy lasers enables intricate designs that would be nearly impossible with traditional cutting tools. Whether you’re crafting delicate jewelry, automotive parts, or artistic installations, laser cutting offers unmatched accuracy and versatility.

Advantages of Laser Cutting

Laser cutting, as a technique, has revolutionized various industries due to the multitude of benefits it offers.

Here’s a look at some of the standout advantages:

Precision and Accuracy: One of the primary benefits of laser cutting is its unparalleled precision. It can achieve intricate designs, sharp edges, and minute details that traditional cutting methods might struggle with.

Consistency: Laser cutters provide consistent results, even for large-scale production. The output remains uniform whether you’re making the first or the thousandth piece.

Speed: Laser cutting is significantly faster than manual or mechanical cutting, which is especially beneficial for large production runs.

Versatility: Laser cutting machines can work with various materials, from metals and plastics to textiles and wood. This flexibility allows industries of all types to benefit from laser technology.

Clean Cuts and Sealed Edges: The precision of the laser ensures that cuts are clean, with smooth edges. For materials like textiles, the heat from the laser can also seal edges, preventing fraying.

Less Waste: Since laser cutting is so precise, there’s reduced waste material. This not only saves on material costs but is also more environmentally friendly.

Minimal Contact: Laser cutting is a non-contact process, unlike traditional cutting methods. This means there’s minimal wear and tear on machinery and no need to change tools for different materials or designs.

Safety: Operators are less exposed to cutting as laser cutters often come in enclosed boxes, reducing the risk of accidents.

Complexity and Detail: Laser cutting allows for complex geometric cuts and designs that would be too intricate for manual processes.

Reduced Damage: Since there’s no physical contact (like a blade or drill), there’s a lower chance of unintentional damage or deformation to the material being cut.

Cost-Effective: While the initial investment in laser cutting technology might be higher, the efficiency, speed, and reduced waste can result in long-term cost savings.

Incorporating laser cutting into a business or project can thus lead to higher quality products, faster turnaround times, and increased profitability. As technology advances, we’ll likely see more industries and creators adopting laser cutting for its numerous advantages.

Choosing the Right Laser Cutting Machine

Selecting the ideal laser-cutting machine is crucial to ensure the best results, cost-efficiency, and smooth operation.

Here are factors to consider when making this decision:

Purpose and Material:

Understand the primary use of the machine. Are you cutting metals, plastics, textiles, or wood? Different lasers are suited for different materials. For instance, CO2 lasers are often chosen for non-metal materials, while fiber lasers are preferable for metals.

Work Area Size:

Consider the size of the material you’ll frequently be working with. Ensure the laser cutter’s bed size can accommodate your typical project dimensions.

Laser Power:

Higher-power lasers can cut through thicker materials faster but may be overkill for finer, thinner materials. Consider the power rating, typically measured in watts. You might need a machine with power above 500W for thicker metals, while cutting paper or textiles may only require under 50W.

Software Compatibility:

Ensure the machine’s software is compatible with your design programs, like AutoCAD or CorelDRAW. Some advanced machines come with proprietary software that can offer added features.

Cooling System:

Powerful laser cutters generate a lot of heat. Check if the machine has an efficient cooling system or if you must purchase an external chiller.

Safety Features:

Look for machines with built-in safety measures like emergency stop buttons, lid protectors that halt opened operations, and venting systems for fumes.

Budget:

Laser cutters vary widely in price. While you shouldn’t compromise on essential features, finding a machine that fits your budget is crucial. Remember, a higher initial investment can sometimes lead to long-term savings due to durability and efficiency.

Ease of Maintenance:

Some laser cutters are more user-friendly when it comes to maintenance. Check the availability of replacement parts and the general user feedback regarding machine upkeep.

Vendor Reputation:

Research vendors and manufacturers. A machine might be fantastic, but you might struggle with potential issues if the vendor’s after-sales support is lackluster.

Expandability and Upgrades:

As your needs grow, you might want to expand the capabilities of your machine. Some laser cutters allow for upgrades in software, power, or additional modules.

Training and Support:

Especially if you’re new to laser cutting, ensure the vendor provides adequate training or resources to get you started. Good customer support can make the initial learning curve much smoother.

Choosing a laser-cutting machine is about balancing your immediate needs with future possibilities. Take the time to assess your requirements, research, and make an informed decision. A well-chosen machine can serve you efficiently for many years, making it a worthy investment.

Future of Laser Cutting

The realm of laser cutting, like many other technologies, is continually evolving. Advancements in technology, research, and industry demands are shaping its trajectory.

Here’s a glimpse into what the future might hold for laser cutting:

Greater Precision with AI:

As artificial intelligence integrates further into manufacturing processes, laser cutting will benefit from enhanced precision. AI can analyze materials in real time, adjusting the laser parameters for optimal cutting, leading to reduced waste and improved quality.

Increased Automation:

The industry is shifting towards fully automated laser-cutting systems. This move not only boosts efficiency but also ensures consistent quality. Robots and automated feeding systems will play significant roles in this transformation.

Eco-friendly Advancements:

Sustainability is becoming paramount in all manufacturing sectors. The laser cutting industry focuses on developing machines that consume less power, have fewer emissions, and operate more efficiently, aligning with global green initiatives.

Faster Machines:

Speed has always been a focus in manufacturing. Future laser cutters will likely operate at even higher speeds, reducing production times and increasing throughput.

Adaptation to New Materials:

As industries evolve, so do their material needs. Laser cutting technology will adapt to cut newer, more advanced materials while ensuring the cut’s integrity.

Integration with the Internet of Things (IoT):

The integration of the IoT means machines will be more interconnected, sharing data and optimizing processes in real time. This interconnectedness will enhance predictive maintenance, reduce downtime, and streamline operations.

Advanced Software Integration:

Advanced software solutions will provide intuitive user interfaces, better design capabilities, and enhanced machine control. This advancement will further democratize laser cutting, making it accessible to more users.

3D Laser Cutting:

While already available, 3D laser cutting technology is poised for more significant growth, especially in industries like automotive and aerospace, where complex component manufacturing is crucial.

Personal Desktop Laser Cutters:

As 3D printers have found their way into homes and small businesses, we might see more compact, user-friendly laser cutters designed for personal or small-scale use.

Enhanced Safety Features:

As the technology grows, so will the emphasis on user safety. Expect future machines to come equipped with more advanced safety features, ensuring user protection without compromising efficiency.

In conclusion, the future of laser cutting is bright and full of potential. As the demand for more intricate, efficient, and sustainable manufacturing processes grows, laser cutting will undoubtedly play a pivotal role in meeting these needs. Both industries and individual artisans stand to benefit immensely from these forthcoming advancements.

Conclusion

Laser cutting has undoubtedly revolutionized the manufacturing landscape, offering unparalleled precision, efficiency, and versatility. From its historical beginnings to its contemporary applications, this technology has consistently evolved, meeting the dynamic needs of various industries. As we glimpse its future, it’s evident that laser cutting is not just a transient technological marvel but a lasting pillar in fabrication and design.

Whether you’re an industry giant or a hobbyist, understanding and leveraging this technology’s capabilities can pave the way for endless creative and functional possibilities. As with any technology, the journey of mastering laser cutting is continuous, but the results—immaculate designs, efficient productions, and sustainable practices—make it an endeavor worth pursuing.