The Advantages and Disadvantages of Glass-Filled Nylon Filaments

Glass-filled nylon is a type of strong and heat-resistant material that is widely used in engineering. It is a synthetic polyamide thermoplastic that offers numerous advantages due to its unique properties.

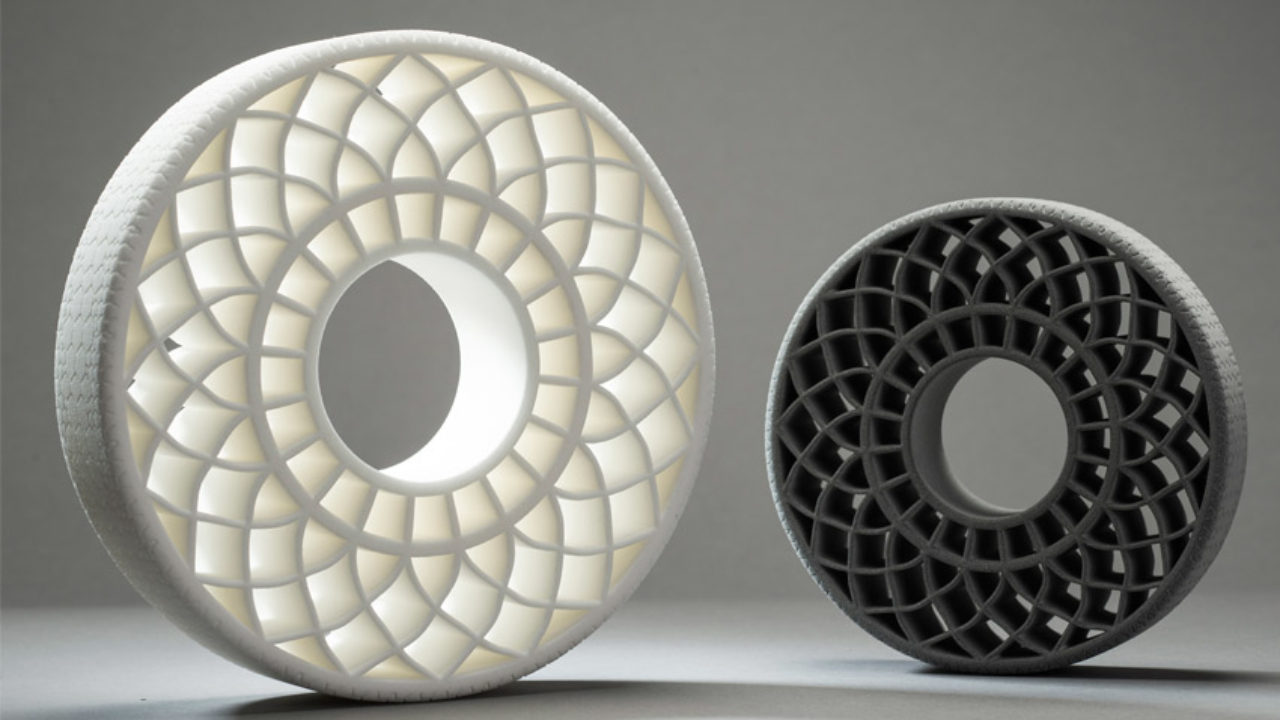

This material is produced by combining powdered glass with nylon resin or by extruding plastic with glass fibers. Another application of glass-filled nylon is in 3D printing, where glass spheres can be added to the base powder in different proportions. The addition of glass to nylon has brought about a paradigm shift in the field of engineering.

Advantages and Disadvantages of Glass-Filled Nylon Filaments

There are various advantages of using glass-filled nylon which are given below:

- Significant improvement in its strength and rigidity – When glass is added to nylon, it becomes substantially stronger, harder, and more rigid than regular nylon.

- Glass-filled nylon exhibits higher resistance to creep, which is the tendency of a material to deform over time under constant stress.

- It also offers better dimensional stability, meaning it maintains its shape and size more effectively when exposed to temperature fluctuations.

- Additionally, glass-filled nylon demonstrates increased wear resistance, making it more durable and long-lasting compared to regular nylon.

- It can withstand higher maximum service temperatures, making it suitable for applications that involve elevated temperatures.

- Enhanced ability to withstand external forces and resist deformation.

- It has superior tensile strength, meaning it can withstand higher levels of pulling or stretching forces without breaking.

- Glass-filled nylon is stiffer, which means it resists bending or flexing more effectively.

- It has a substantially lower thermal expansion rate, meaning it is less likely to change its shape or size when exposed to temperature changes. This property is advantageous in applications where dimensional accuracy is crucial.

- It exhibits good fatigue strength, allowing it to endure repeated stress cycles without failure.

- It possesses high mechanical damping properties, which means it absorbs and dissipates mechanical energy, reducing vibrations and noise.

These characteristics make it an ideal material for parts that are subjected to high static loads in high-temperature environments.

Disadvantages of Glass-Filled Nylon Filaments

Despite its many advantages, glass-filled nylon also has some disadvantages, which are as follows:

- Significantly higher cost compared to regular nylon – The addition of glass fibers increases the production cost, making glass-filled nylon more expensive.

- Glass-filled nylon tends to be more brittle than regular nylon. This means it is more prone to cracking or breaking under impact or excessive stress.

- The glass filler in glass-filled nylon is quite abrasive, which can cause increased wear and tear on cutting tools and other equipment used in machining processes. It can also lead to the erosion of mated parts due to increased friction.

- Glass-filled nylon is heavier than regular nylon, which can be a disadvantage in weight-sensitive applications.

- Glass-filled nylon has significantly weaker weld lines, which are the lines formed during the fusion of molten plastic in injection moulding. These weaker weld lines can compromise the structural integrity of the final product.

- Glass-filled nylon exhibits anisotropic properties, meaning it shrinks and expands unevenly. This could pose challenges in achieving dimensional accuracy and consistency in moulded parts.

In 3D printing, nylon materials are known for producing strong and durable parts suitable for both functional prototyping and end-use projects. Glass-filled nylons particularly outshine regular nylons with respect to long-term wear resistance, higher stiffness, and superior heat deflection resistance.

Different types of glass-filled nylons can be used for selective laser sintering (SLS) and Multi Jet Fusion (MJF) 3D printing processes. All printed nylons, including glass-filled ones, exhibit high levels of strength, stiffness, and temperature resistance. However, glass-filled nylons provide enhanced performance in terms of wear resistance, stiffness, and heat deflection.

For instance, PA66-GF30 and PA6-GF30 are nylon filaments infused with 30% glass fibers, which. offer enhanced strength, rigidity, and heat resistance compared to standard nylon filaments. They are ideal for applications that require high mechanical performance and dimensional stability in 3D printing projects.

In injection moulding, glass-filled nylon offers improvements over regular nylon in terms of hardness, tensile strength, and dimensional stability. By adding glass fibers to nylon, the material’s heat resistance and resistance to UV light can be enhanced.

Injection moulding projects benefit from the increased rigidity, improved hardness, superior tensile strength, increased creep resistance, greater dimensional stability, and high mechanical damping provided by glass-filled nylon.

It is important to note that nylon, and particularly glass-filled nylon, can be more prone to warp due to non-linear shrinkage. Therefore, it is important to select the appropriate type of nylon that suits the specific needs of a project. Moreover, working with glass-filled nylon can present dimensional challenges when dealing with semi-crystalline materials. Thus, it is necessary to carefully evaluate the trade-offs associated with the use of glass-filled nylon in each application.

In summary, keeping in mind the advantages and disadvantages of glass-filled nylon, glass-filled nylon provides numerous advantages and offers good mechanical properties, fatigue resistance, noise damping, and excellent bearing and wear resistance, if it is handled carefully and properly.